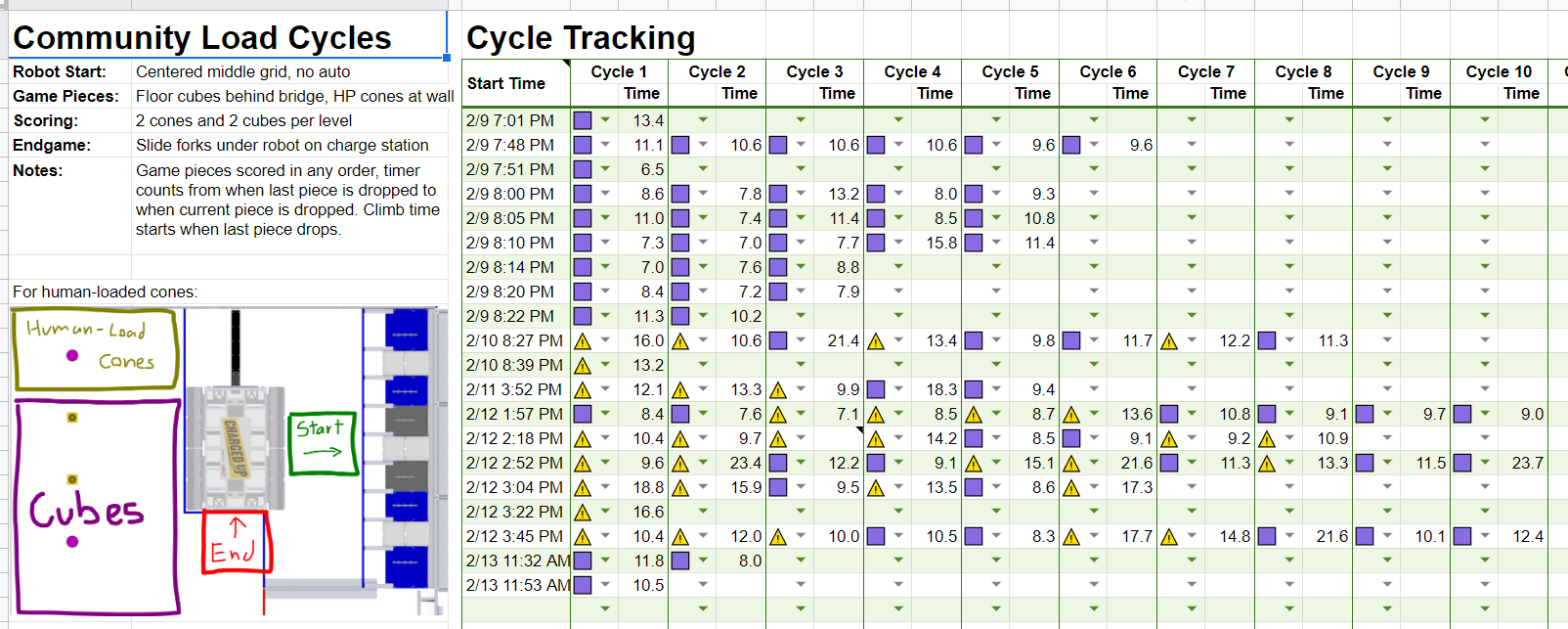

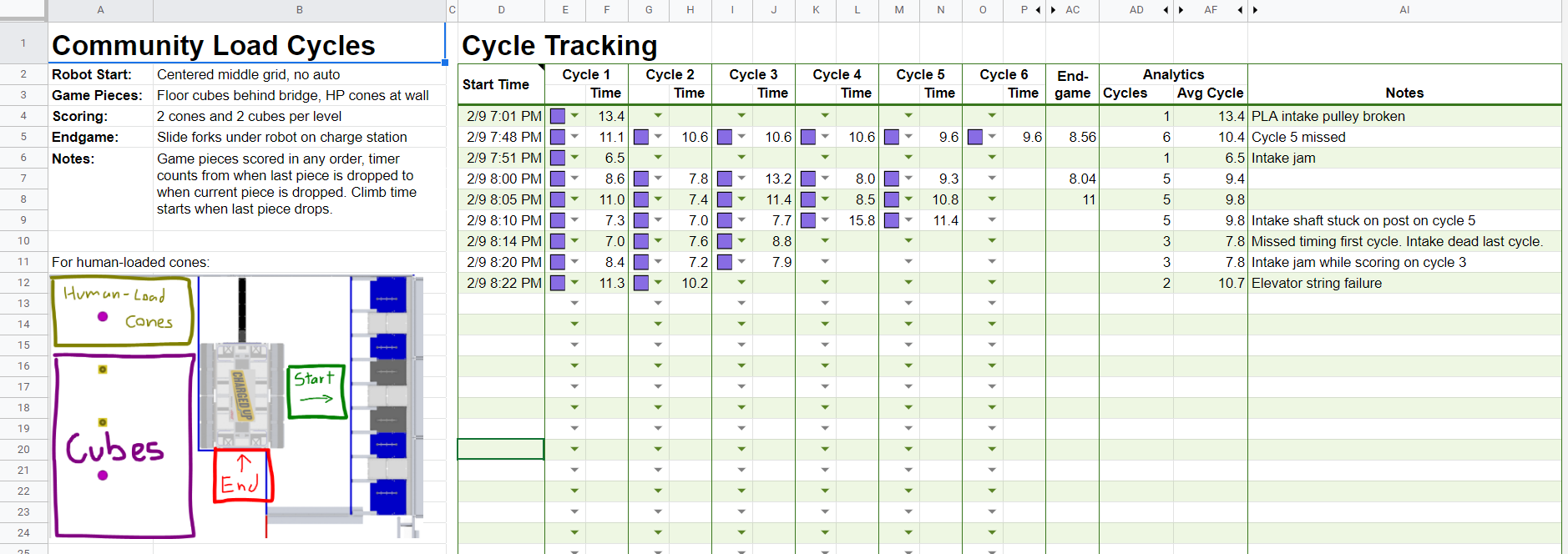

On Saturday, Comp and the drive team went into San Jose to practice driving on 254's full field while the hardware teams finished the R2B2 rebuild.

Comp

The practice session went well, and below are Mike's notes as they were posted in Slack:

- When the battery gets really low, the robot struggles to keep the arm up for L3 scoring. We might need to further adjust the gear ratio, but we can play around this for Port.

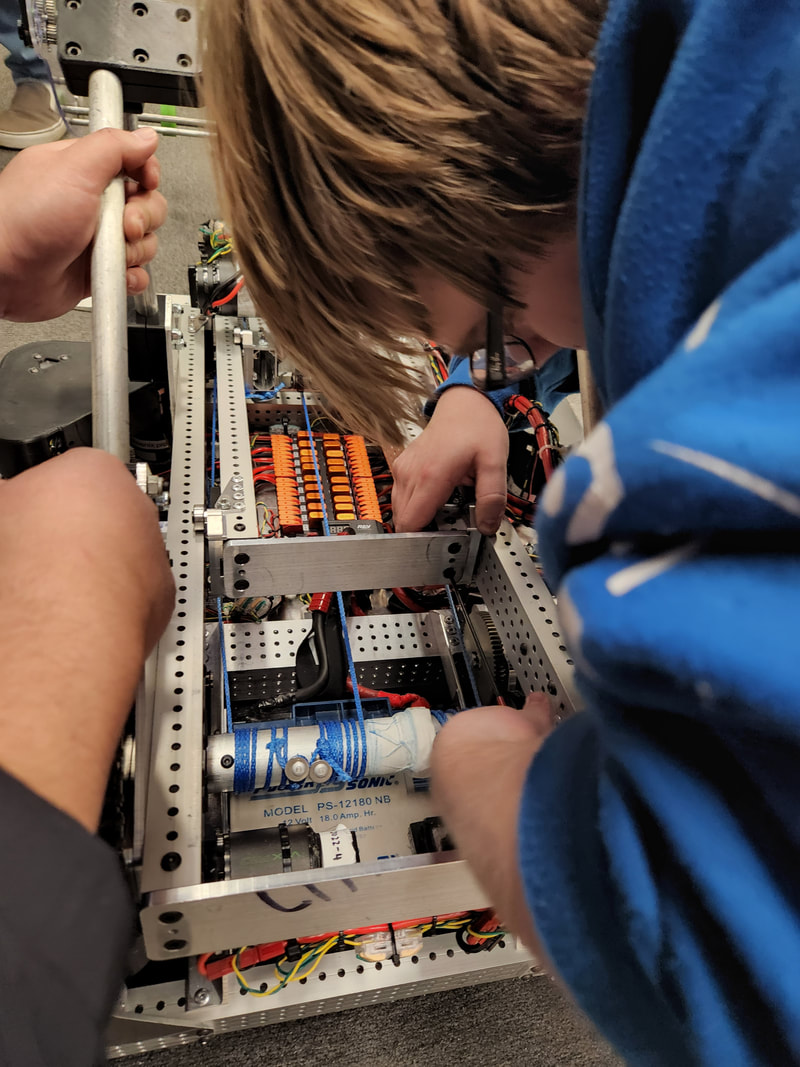

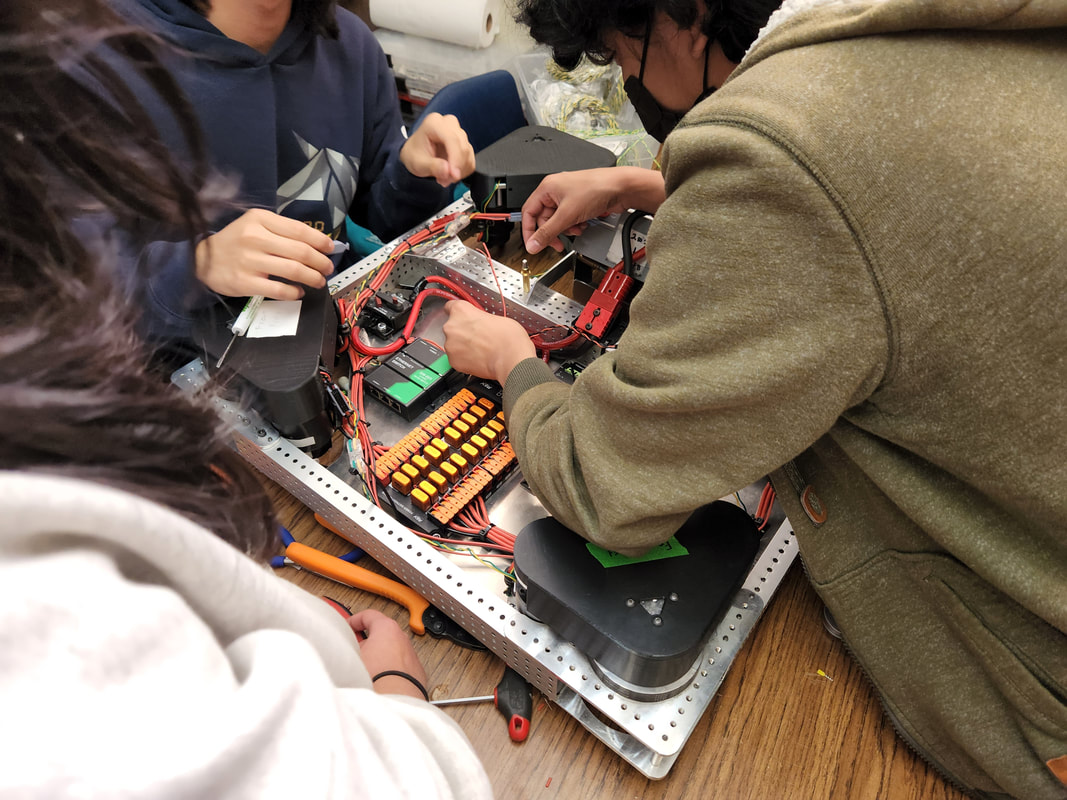

- We had one falcon power wire come out of the PDH. There is no strain relief so it just popped out. We need to fix this.

- We had multiple bad solder and strip joints in the CAN loop. The CAN issues are brutal and hurt big time in practice. We must get better and inspect all cables

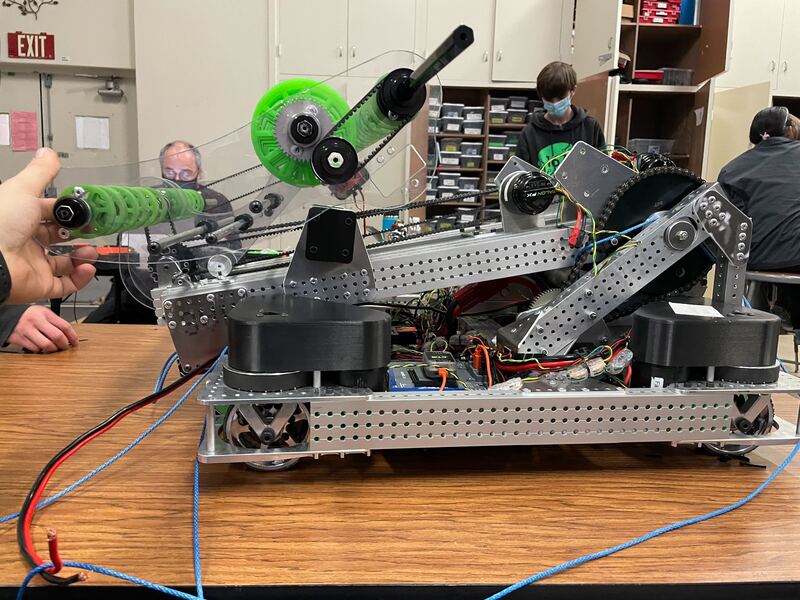

- The e-chain mount on the arm broke. This needs an AL backplate

- One of the steering falcon shafts is coming loose. We should inspect and consider adding a output shaft support bearing like poofs do. Poofs also said they swap all their falcon nose bearings out.

- when switching swerve tread, one of the wheels was almost impossible to remove because of too much loctite.

- Bumpers are still too low.

- The rivets in the bellypan sheared. Let’s use high strengths.

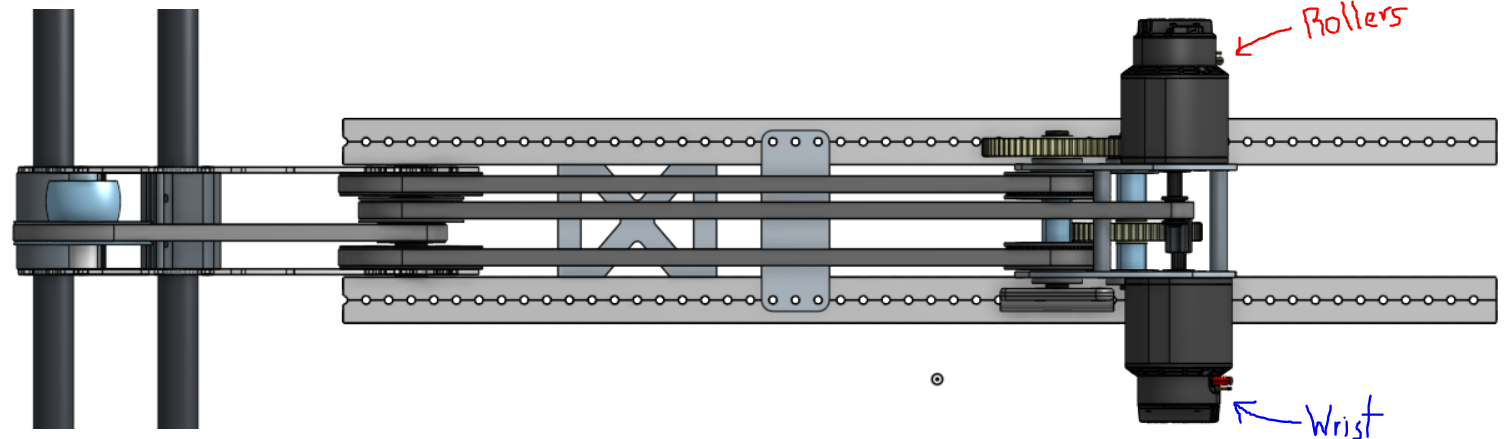

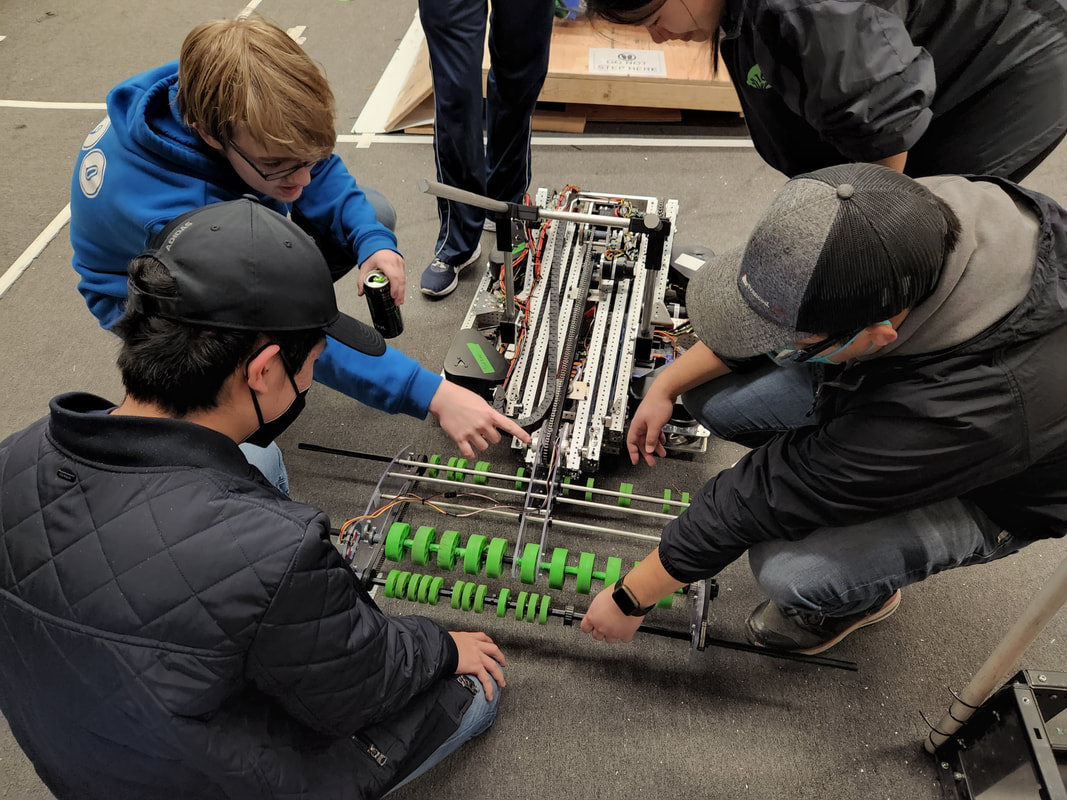

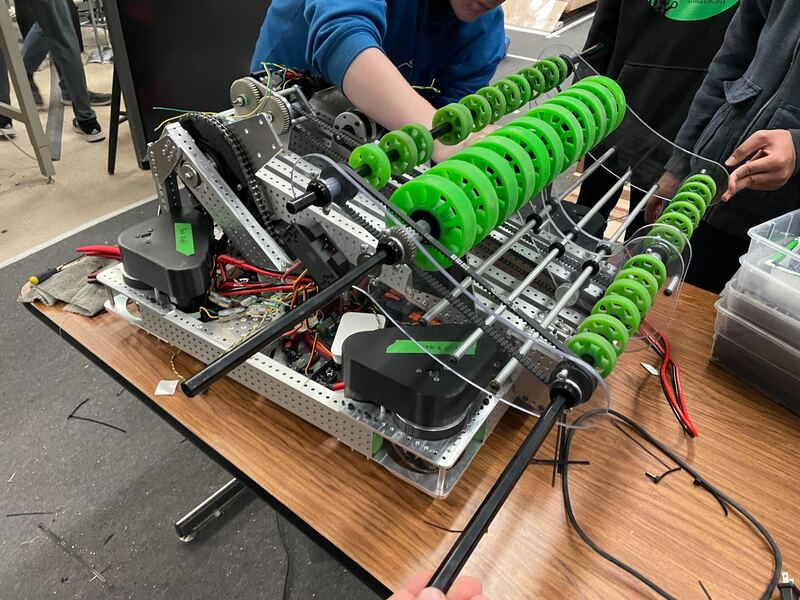

- Intake power belts are still falling off/slipping and results in low/no power to the intake rollers. This is our most common issue.

- Grabbing from the shelf was working better than grabbing from the ramp. Both are challenging for our robot

- Cubes on the ground are proving tough for the intake to hold onto. We hope the newest intake is better in this regard.

- Intake skew is still a problem. We hope the new intake fixes this too.

- Software sequences are slow and could be sped up in places.

- The wrist chain was loose but never really skipped, which was good.

- Elevator DOF was solid

- Arm DOF was fine except for a few times the flathead holding the elevator drum backed out causing chain rub. There is potential gear tilt again that we should inspect.

- The 1/8” inner intake plate snapped. We need a spare cut.

- The swerve twitches at the start of auto, sometimes causing a cone miss. We need to look into ways to mitigate the twitching.

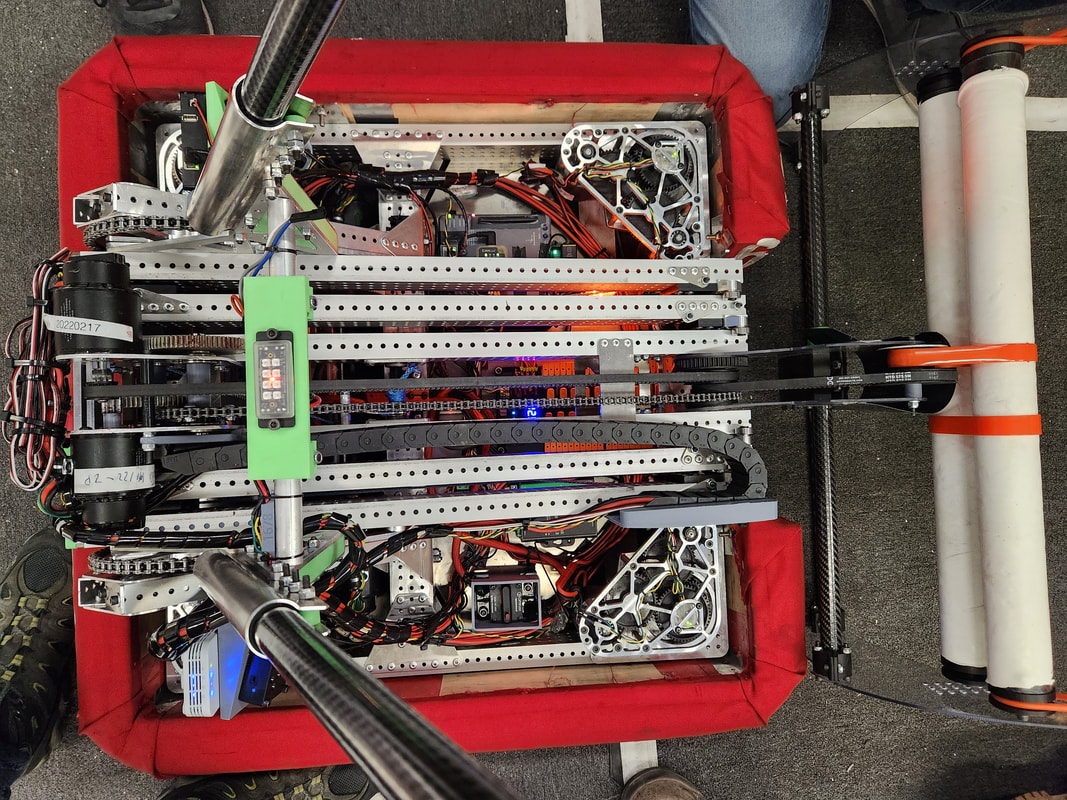

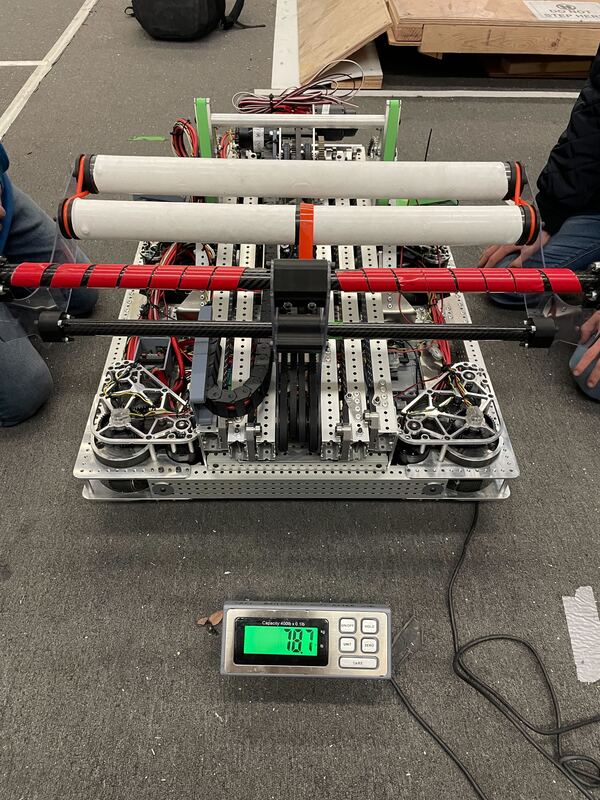

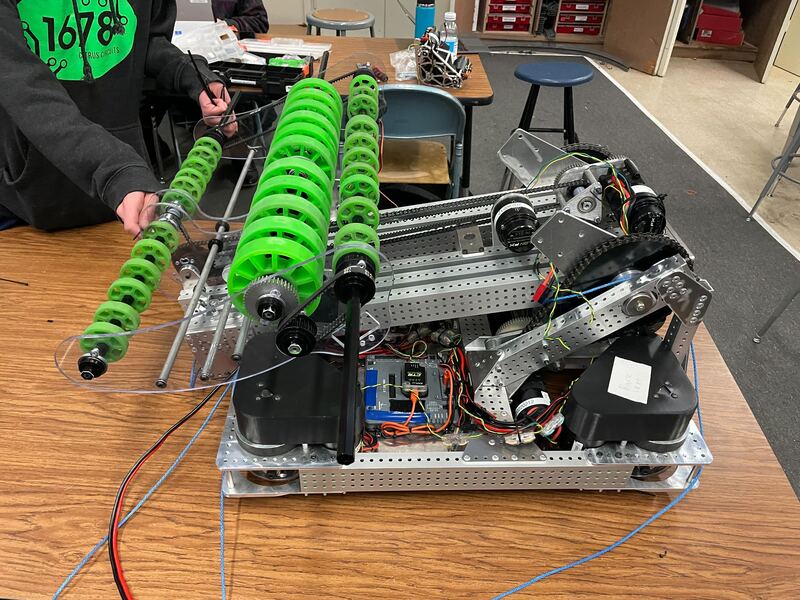

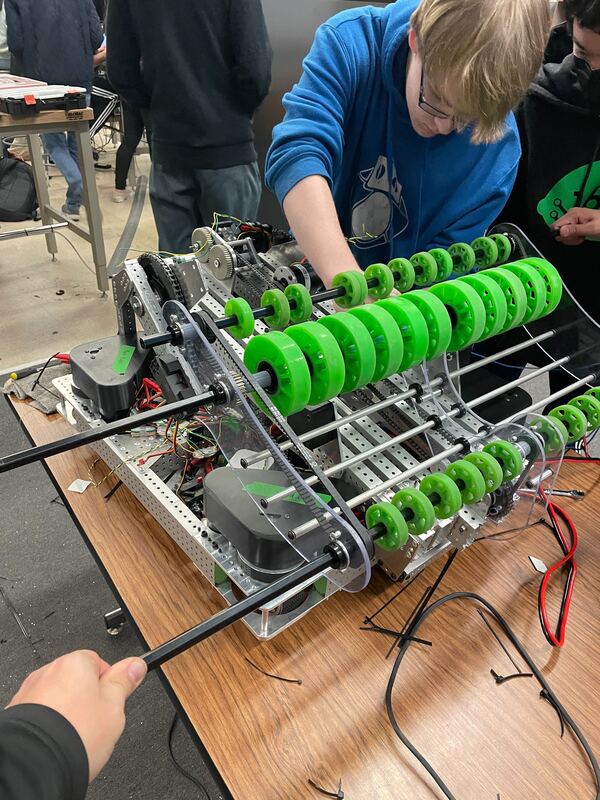

R2B2

R2B2 was mechanically and electrically complete by about 5pm today, finally ready for drive testing.

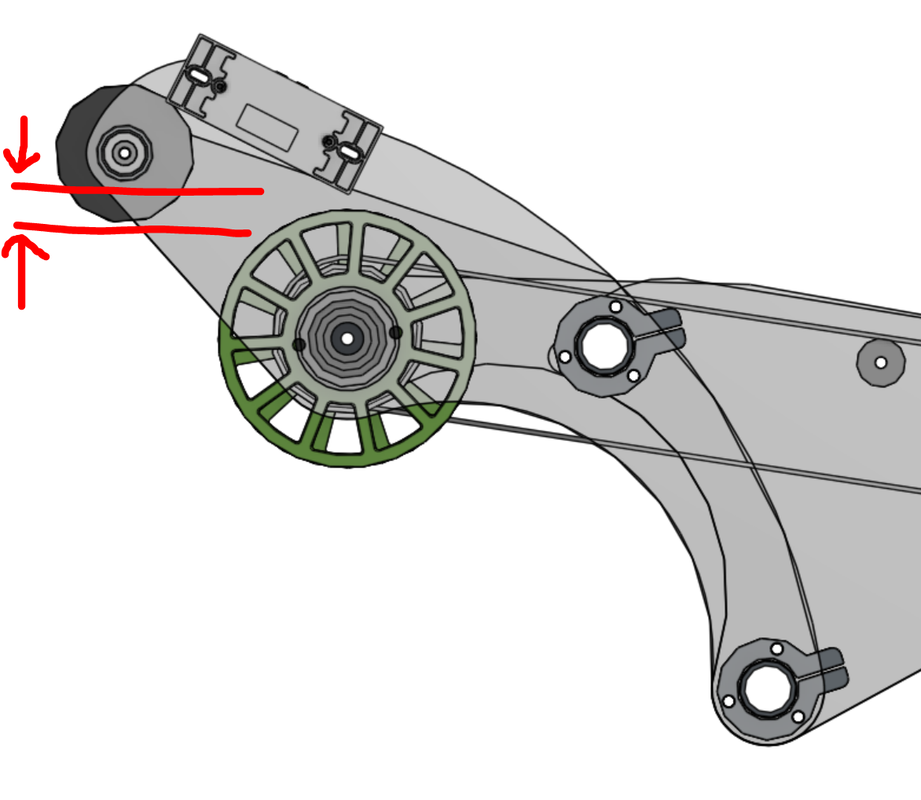

Immediately after this, we found that the wrist doesn't have enough torque to lift the intake with a game piece in it.

Immediately after this, we found that the wrist doesn't have enough torque to lift the intake with a game piece in it.

Beta is doing better than comp though, since Comp's wrist had fully snapped in half.

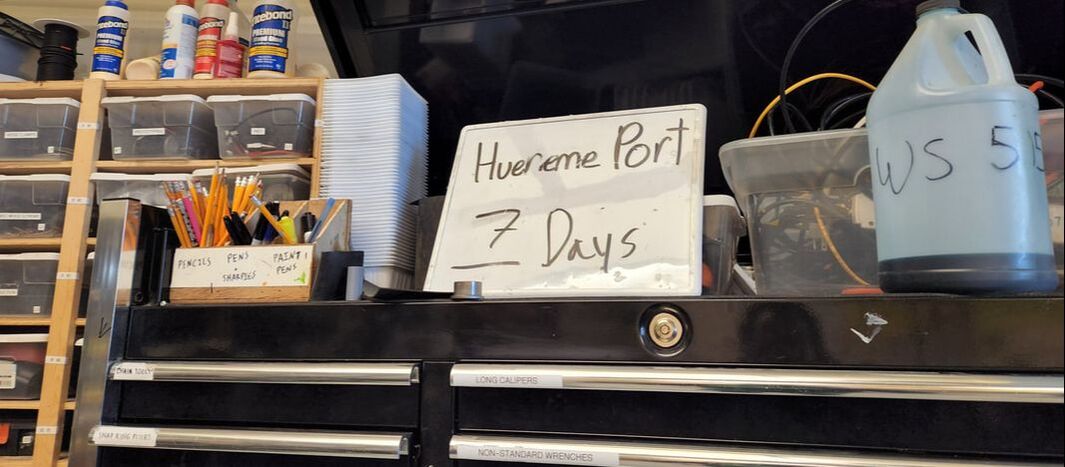

5 days until competition.

RSS Feed

RSS Feed