Build blog 2020

episode 8 - the last blog

welcome!

|

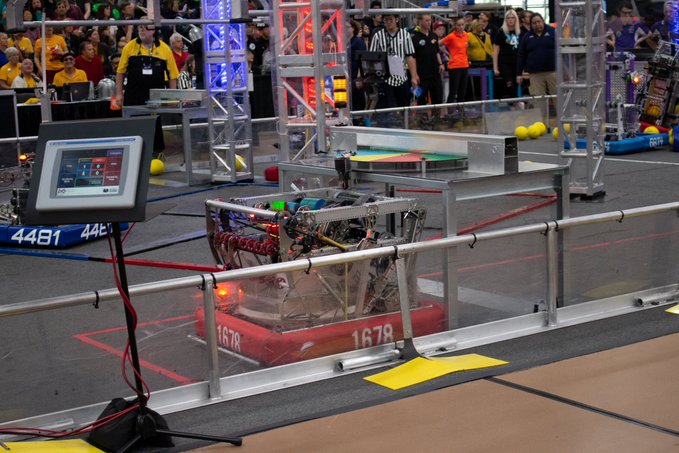

Snoke told Kylo Ren "When I found you, I saw raw, untamed power, and beyond that, something truly special." We are so happy to have been able to inform you on what our team has been doing the past few weeks for the 2020 FIRST Robotics build season! The students have put in lots of hours and dedication to create our robot in time for our first competition, the LA North Regional, which took place from February 29 to March 1. Keep reading to see what each subteam worked on during the last week of build season and we’ll catch you leia!

|

business and media

|

Hardware Electrical

|

|

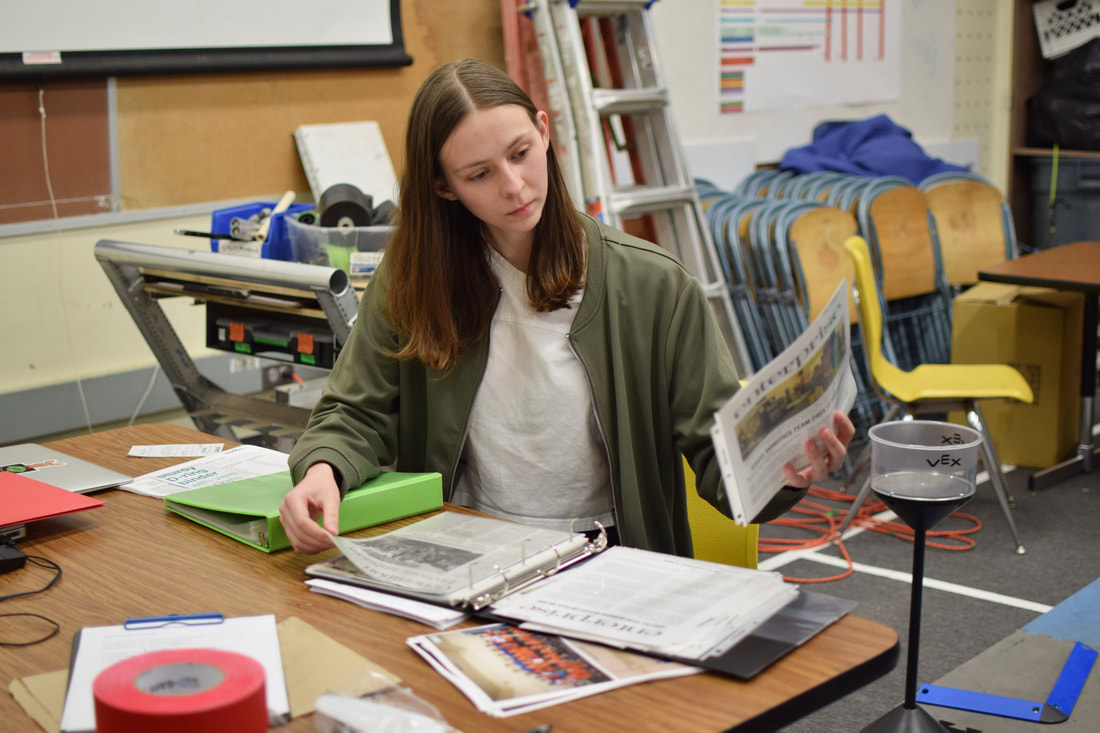

Business and Media worked on the sponsor panel for the robot, the March newsletter, and the apparel inventory. The week before the regional was also our team’s Sponsor Open House, so the Business and Media subteam showed our 2020 sponsors around and explained how our team operates and what each subteam contributes to the team. They also prepared for the LA North Regional by putting together the pit display, banner, buttons, stickers, and other giveaways!

|

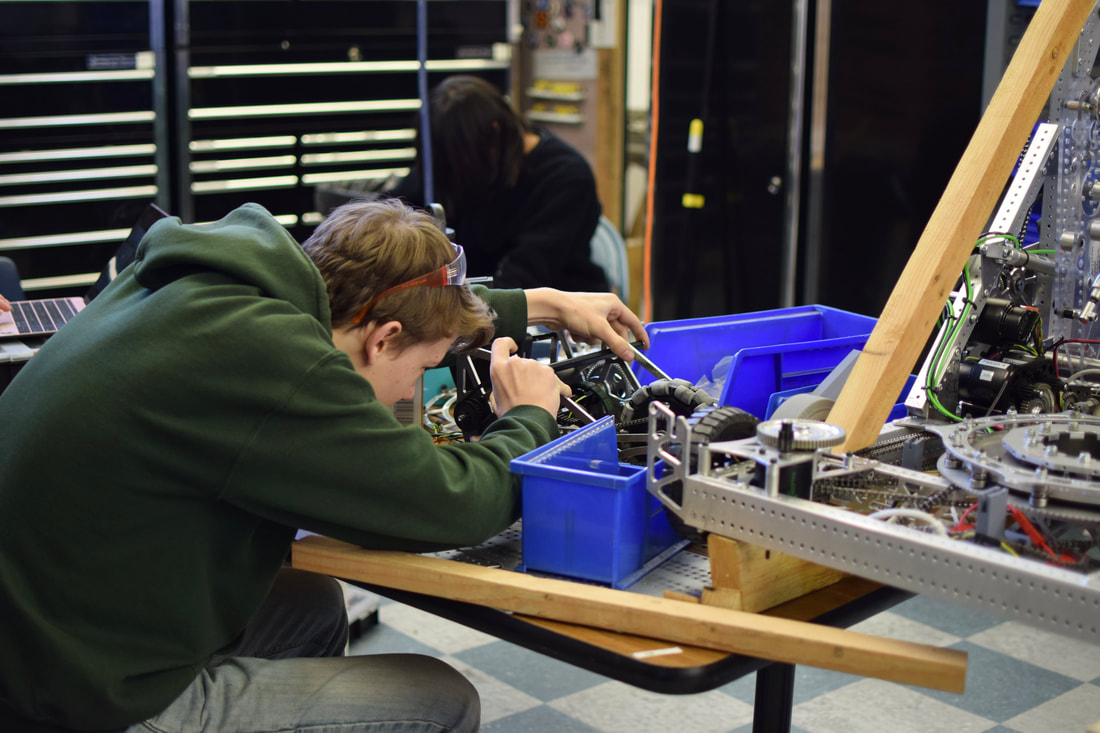

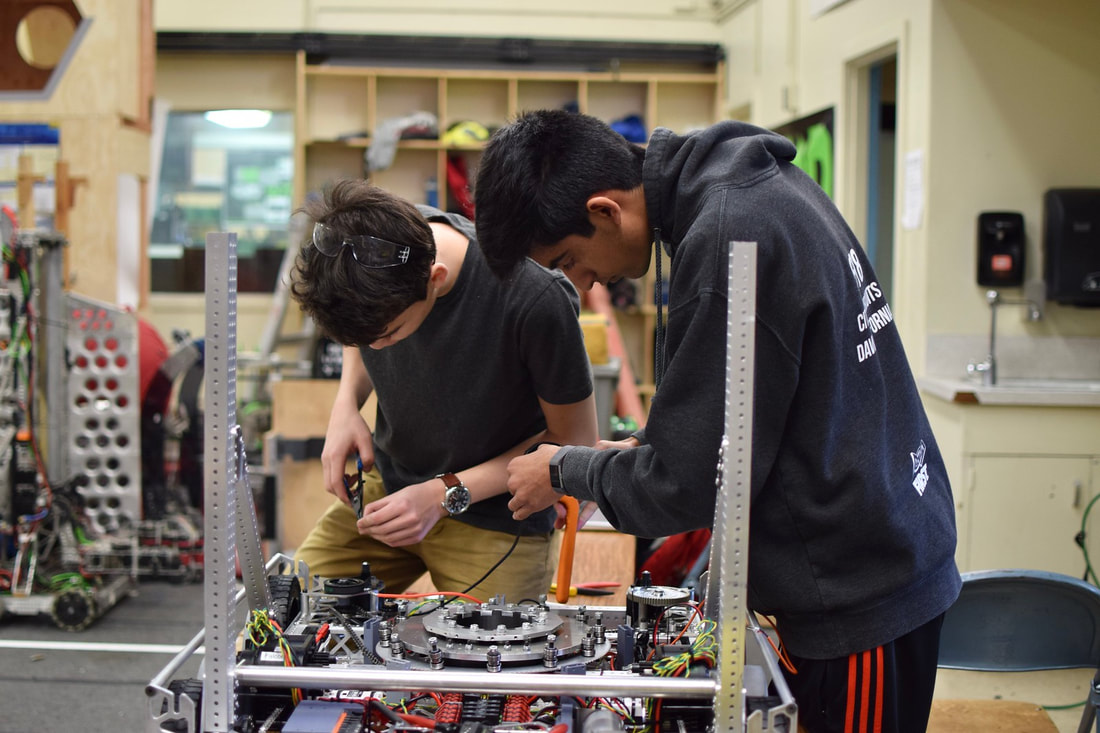

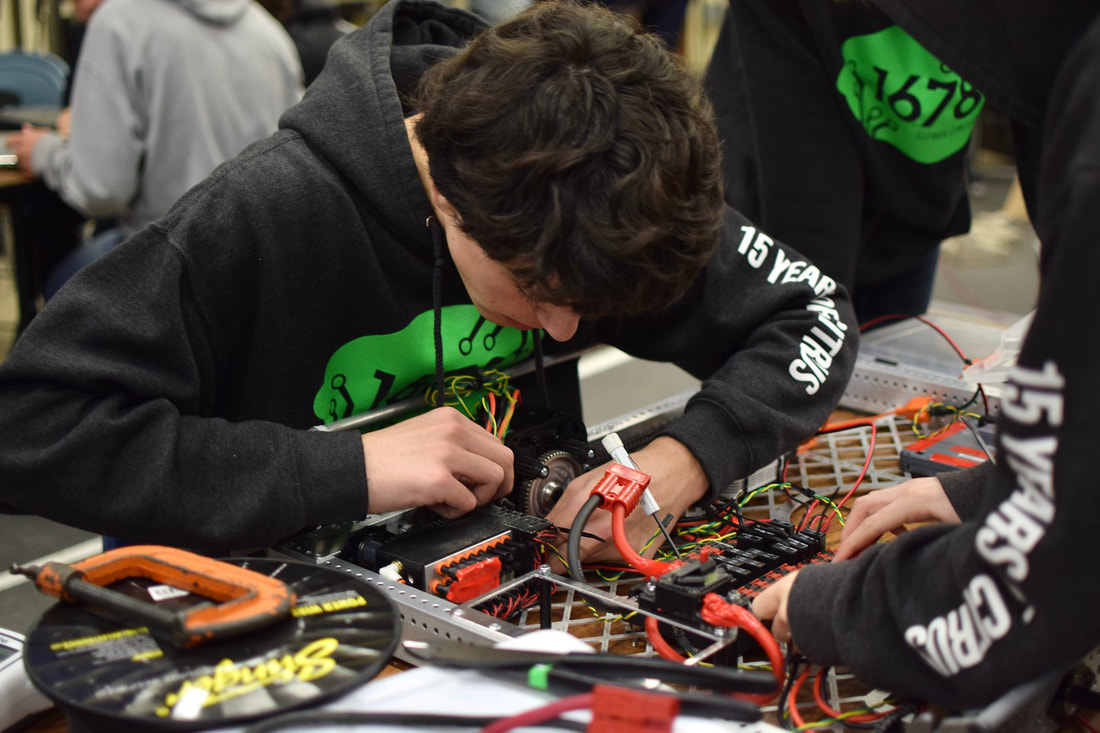

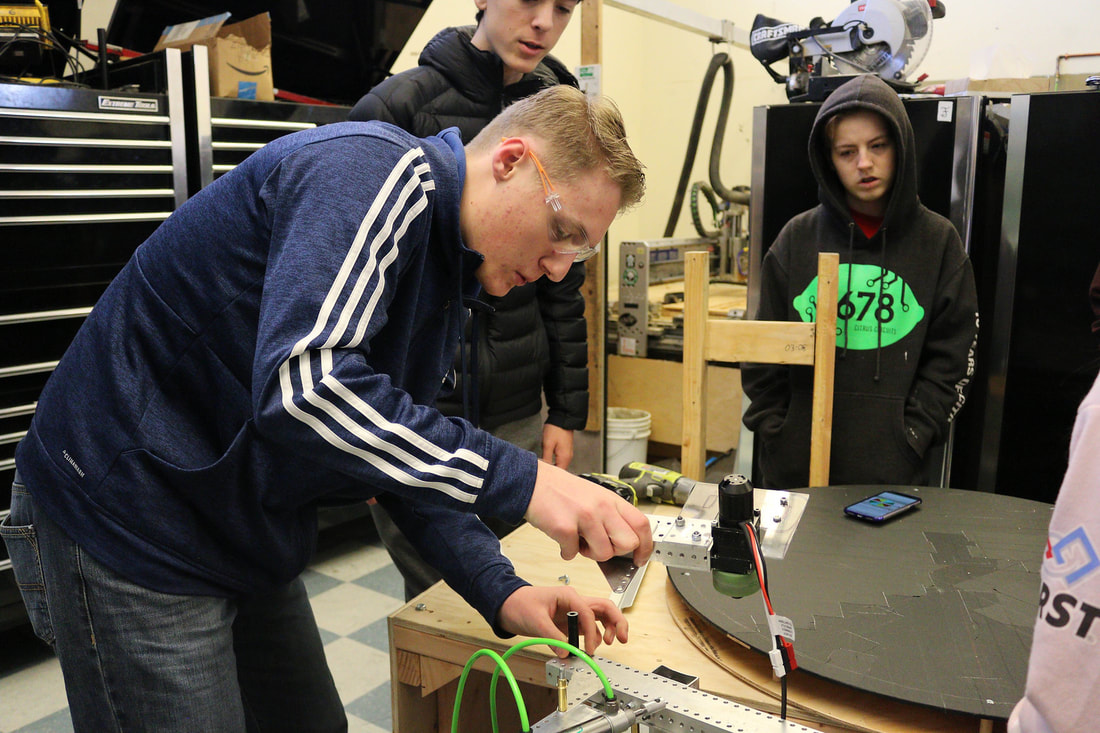

The Hardware Electrical subteam worked hard this past week, including extra meetings, to wire the turret and other mechanisms onto the Competition robot. They also worked disassembling the Falcon 500 motors and putting loctite (a type of glue liquid that locks in a bolt) on the Falcon screws. Some members of the subteam also helped Citrus Service by working on the inventory and making robot bumpers that are needed during competitions.

|

hardware fabrication

|

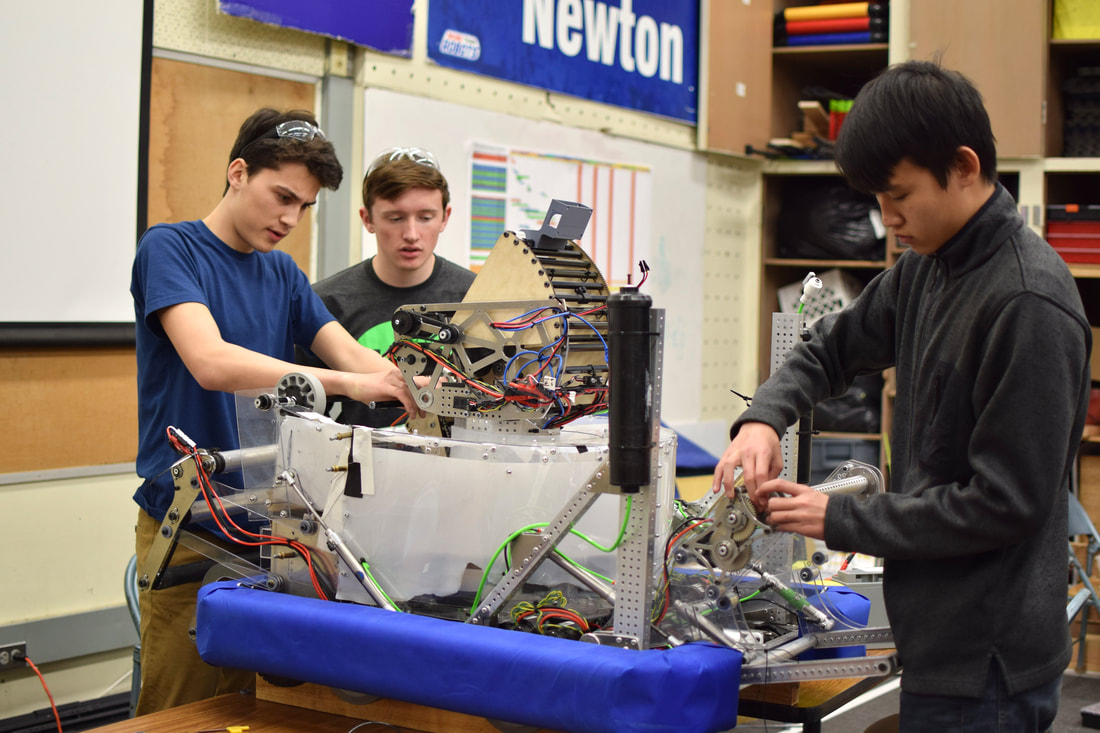

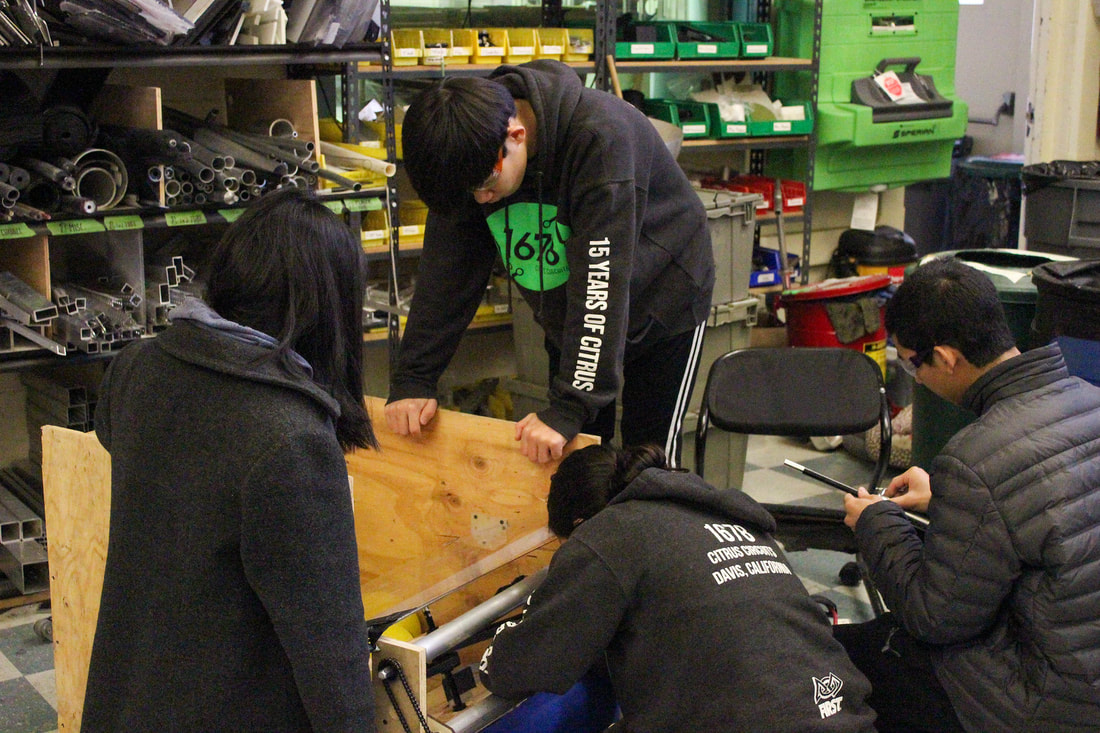

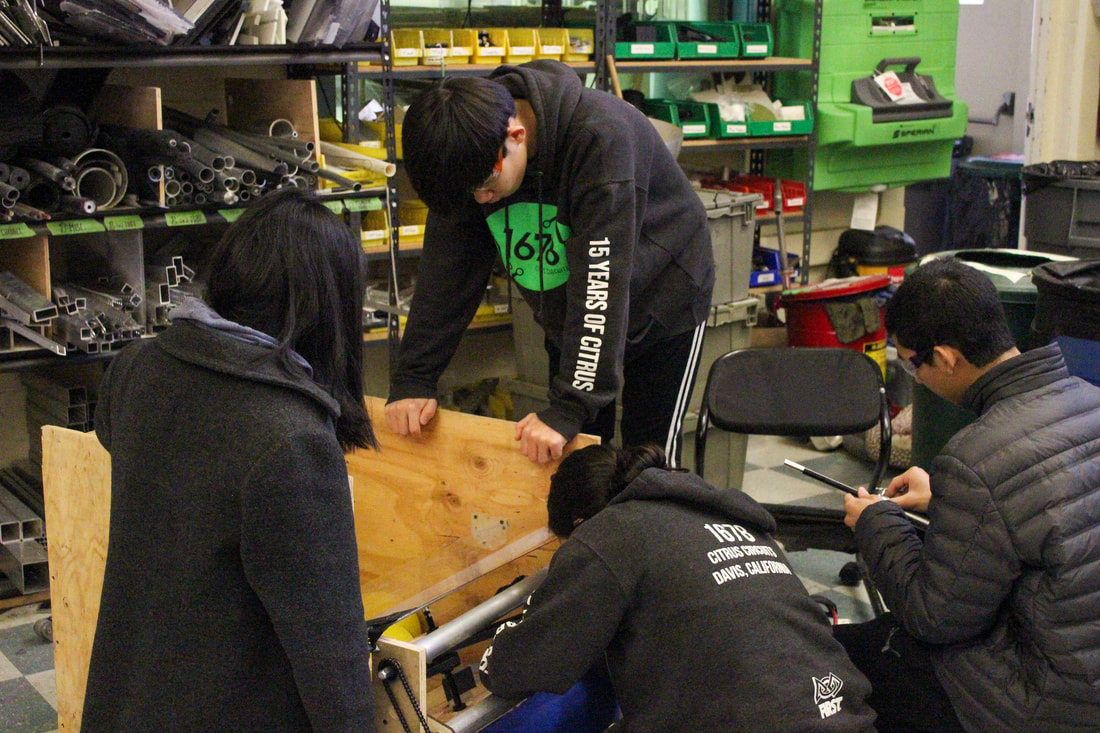

The week before the LA North Regional, Hardware Fabrication fabricated robot parts for the Wheel of Doom, the Competition robot climber, and the necessary spare parts needed for our team to be ready for the regional. For the intake, the subteam finally finished the deployment system for the pop-up bar on the front of the robot, moved all of the mecanum wheels to the corners of the intake, moved the Falcon motor so it is above the intake instead of below it, and changed the overall geometry to avoid interference with the shooter. New members contributed a substantial amount of effort when it came to making last minute parts, as well as assisting in the assembly of our robot. They act like veteran members on the team because of their strong work ethic, and many returning members say that sometimes it’s hard to tell the difference at this point! Hardware Fabrication found themselves short on time, so the workload increased a fair amount in order to stay on schedule and complete the Competition robot. One problem they encountered was that the robot was over the 125-pound weight limit, which changed some design decisions in order to meet weight requirements. Due to the limited amount of time left until LA North, Hardware Fabrication had extra meetings in order to finish the Competition robot in time!

|

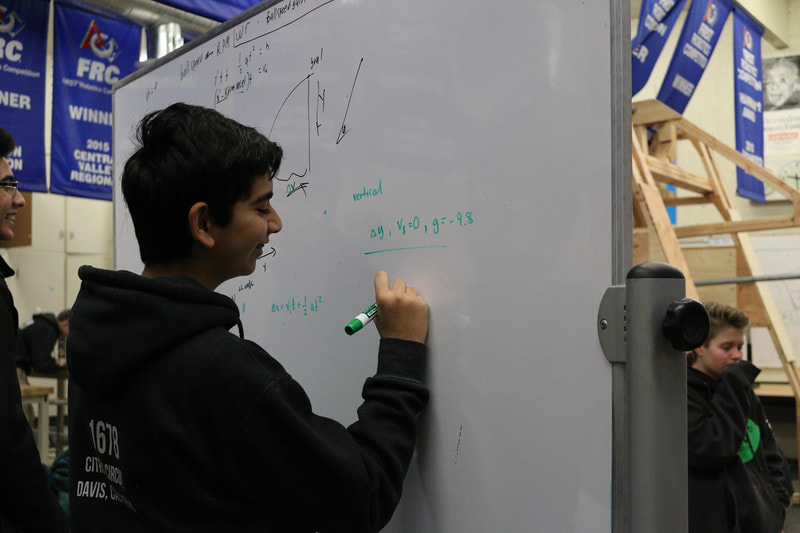

Hardware design

Hardware Design worked on doing final iterations of the intake, shooter, control panel, and climber before the LA North Regional. New members contributed greatly toward the assembly process by helping to put together the climber, shooter, and Wheel of Doom for the Competition robot. They prepared for the competition by making changes to help the robot perform at its best, and overseeing fabrication of spare parts and mechanisms in case of mechanical failure. The main challenge was building a robust climber. The subteam didn’t have a tested solution for LA and having three days to accomplish the task was a challenge. The robot was about two pounds overweight, so having to optimize the systems to lose weight was also a challenge. On the climber they moved to spectra cable as opposed to belt for transmitting power to the telescoping arms. For weight, Hardware Design removed some unneeded pneumatic cylinders and decreased the number of solenoids on the robot.

|

software scouting

|

The Software Scouting subteam finished up the scouting system for the LA North Regional. Front-end finished the match collection app and focused their efforts into the pit collection, match strategy view, and picklist editor spreadsheet. Back-end worked on finishing calculations for LA North. They organized the scout training by preparing the user documentation, testing the process, and setting up for the actual scout trainings. Due to limited time, Software Scouting picked up the pace to complete their tasks. One issue the subteam struggled with was dealing with picklist editor. It is really tricky, and it requires members to learn a new language known as Google Appscript in order to make the picklist editor spreadsheet customizable. Luckily, there are few members who are experienced with this language who helped out the members to complete the picklist editor spreadsheet on time!

|

software robot

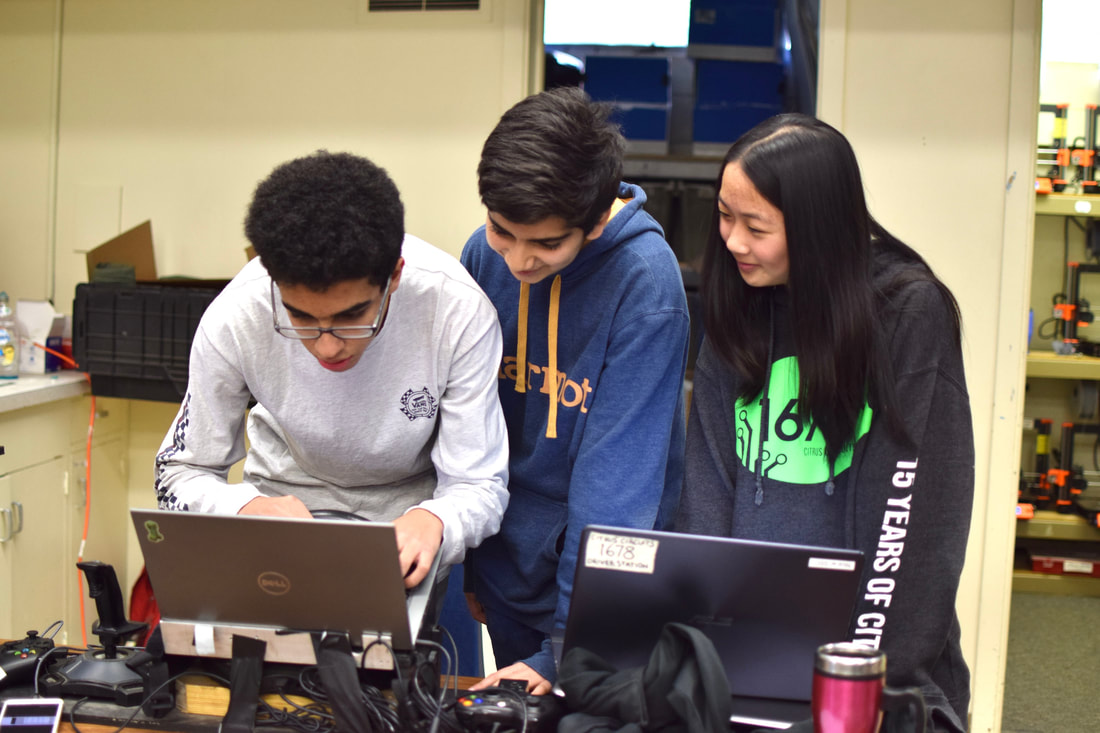

Software Robot worked on trying to tune vision for the new shooter, so they can get accurate near and far shots during a match. It required good data points, and the subteam modeled RPM and hood angles so as the robot got closer to the goal the hood angle decreased and as it got farther the angles increased. The subteam also worked on lots of climber testing so our team could achieve a good climb and buddy climb. New members worked on the test bench (which is used to test code on motors and solenoids without having a robot), came to extra meetings, and wrote the eight-ball auto with the help of veteran members. Software Robot had been running system checks and the limited time meant that lots of work needed to be done in the short period. They made sure auto path tracking had correct vision, and made sure different gears and drivetrain were in correct ratios. One challenge the subteam encountered in the past week was tuning the vision hood angle making sure it was time automated, but they worked with the Hardware subteams to make sure the system ran smoothly.

|

strategy

|

Strategy reviewed Israel District Events 1 and 2 videos and match statistics in preparation for the LA North Regional, however, not all the information was uploaded which made it harder to analyze. In addition, the scouting data from LA North Regional will help our team for future competitions. Strategy will analyze the information to help which teams are the most capable and who is the most ideal a-lime-ance team!

|

deep dive: scouting

Scouting is integral to our team's competitive success. Scouting allows us to create a well-informed picklist (ordered list of teams we want to pick in the alliance selection process) and helps us to tailor our qualification match strategy to the strengths and weaknesses of our alliance partners and opponents.

Scouting collects and processes data about individual robots that is not provided by other sources, such as The Blue Alliance. The scouted data is represented visually, as both numbers and graphs, for the strategists to use in match strategy and picklist creation. This allows strategists to form effective match strategy during qualifications by applying collected information on the capabilities of our alliance partners and the opposing alliance, which can impact the strategy used in each match. The information gathered in scouting also allows the strategists to have more information when creating the picklist for the elimination round, as they can review statistics for each robot and how they performed during the competition.

There are two different types of scouting: Subjective and Objective. Subjective Scouting (formerly Super Scouting) is where one person scouts subjective qualities all three robots of one alliance during a match. They scout qualities of robots on an alliance, such as agility and speed relative to the other robots on the same alliance, and rank each one. Objective Scouting is where one person scouts one robot and records their objective actions (such as shots made, climb, etc.) throughout a match. For scout training, the objective scouts read through a user documentation created by Software Scouting before their training session and took a test in the form of a Kahoot game. Afterward, they proceeded to all scout the same robot, which continues for several hours. Subjective scouts are trained by mentors of the Strategy subteam to know what to look for in subjective scouting.

Scouting collects and processes data about individual robots that is not provided by other sources, such as The Blue Alliance. The scouted data is represented visually, as both numbers and graphs, for the strategists to use in match strategy and picklist creation. This allows strategists to form effective match strategy during qualifications by applying collected information on the capabilities of our alliance partners and the opposing alliance, which can impact the strategy used in each match. The information gathered in scouting also allows the strategists to have more information when creating the picklist for the elimination round, as they can review statistics for each robot and how they performed during the competition.

There are two different types of scouting: Subjective and Objective. Subjective Scouting (formerly Super Scouting) is where one person scouts subjective qualities all three robots of one alliance during a match. They scout qualities of robots on an alliance, such as agility and speed relative to the other robots on the same alliance, and rank each one. Objective Scouting is where one person scouts one robot and records their objective actions (such as shots made, climb, etc.) throughout a match. For scout training, the objective scouts read through a user documentation created by Software Scouting before their training session and took a test in the form of a Kahoot game. Afterward, they proceeded to all scout the same robot, which continues for several hours. Subjective scouts are trained by mentors of the Strategy subteam to know what to look for in subjective scouting.

EPISODE 7 - THE GAME AWAKENS

WELCOME!

|

As Finn once said, “We'll figure it out. We'll use the Force.” The students are figuring out how to quickly finalize our robot for the LA North Regional by using skills they have learned throughout the year. Continuing reading to see what each subteam is working on in the lime-ited time we have left!

|

HARDWARE FABRICATION

|

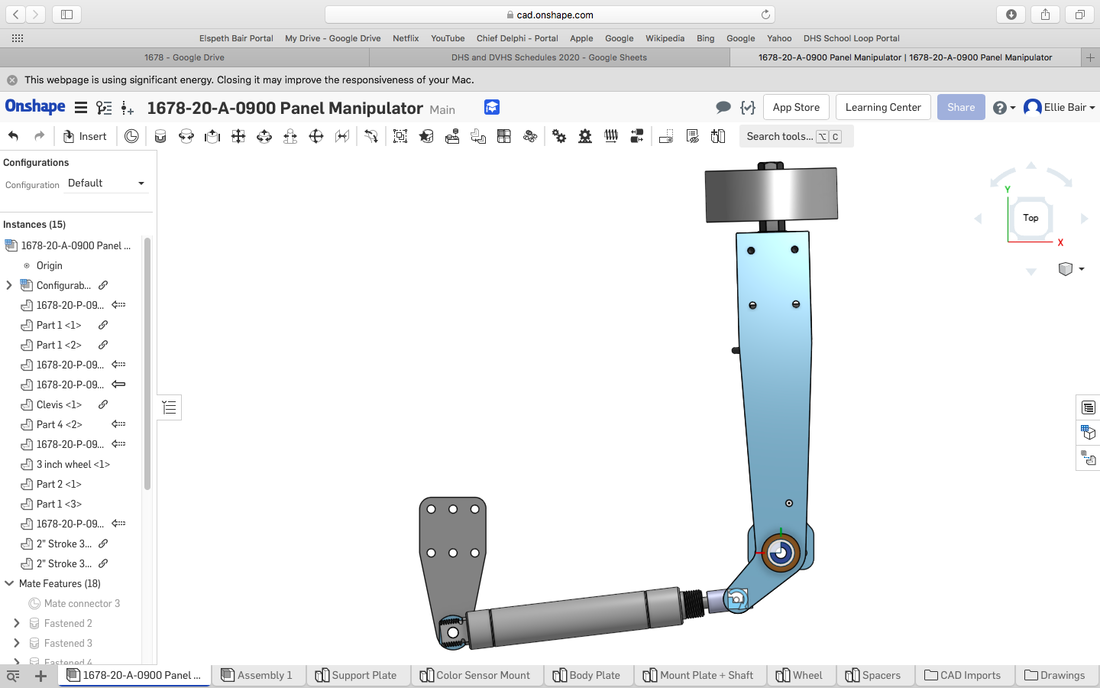

This week, Hardware Fabrication has been fabricating a large percentage of second quantity parts to get the Competition robot fully functional as soon as possible. The subteam disassembled the Alpha robot from last year and made extra parts, including a few key components that were redesigned, in preparation for the LA North Regional. These include dimensional adjustments on the shooter tower, the intake, and the Wheel of Doom. Fabrication has also been working on a brand new mechanism for the control panel mechanism! This mechanism will be able to do both position and rotation control, and is even equipped with a color sensor for more accuracy. They also prototyped a different indexing system just in case the indexer doesn’t run smoothly. The main challenge the subteam has been facing recently is figuring out how to efficiently distribute parts among the CNC routers. They have spent time organizing different parts into different groups classified under what router is capable of running a part.

|

HARDWARE DESIGNHardware Design has been doing a lot of on-robot prototyping in order to figure out where inconsistencies are coming from, and from there they iterate the design as quickly as possible based on findings. They are refining details on the second and third revision of mechanisms that will be placed on the Competition robot. The subteam also needs to make changes on the indexer, shooter, and intake on its third revision, while new members have been supporting testing, helping with quick fixes, and detailing assemblies in CAD (Computer-Aided Design) after big changes. Many new members have been helping greatly with assembly, part drawings, tool paths, and helping to make supplementary parts for the mechanisms such as printing spacers or pocketing in the CAD (pocketing means adding holes or removing unnecessary material to lighten a robot part). The subteam still doesn’t have a solution for consistently hitting shots from behind the trench. The Design subteam is also working to improve communications with Hardware Fabrication in order to maintain version control for each design to use on the CAD documents, which have a time-lime with versions and branches.

|

HARDWARE ELECTRICAL

|

This week, Hardware Electrical has been wiring the turret on the Beta robot and other mechanisms that are being mounted onto the robots. New members have contributed by helping with wiring checks, which is where they check all connections on the robot to make sure everything is plugged in correctly without any exposed wires, fabrication, and cutting their new order of crimps, which are little metal connectors that are squeezed onto wires. The subteam has been struggling to wire the mechanisms because there are other existing mechanisms obstructing their view, but they have been trying their best to start the wiring at the parts in the center that are most difficult to see, then wiring their way out in order to overcome this challenge!

|

SOFTWARE ROBOTThis week, Software Robot has been working on more autonomous routines, and they have already finished four eight-ball autos and hope to get another ten-ball auto soon before the LA North Regional! They are working to make the turret hold its position better so it is always in place. Currently, it is not as smooth and it is not holding as much as it potentially can. The turret also had its position altered to make sure the difference between actual and entered values does not create issues with the new shooter. Safety resets have also been modified by changing soft limits on the robot. The robot’s movement measurements have also been refined, and the motor on the intake has been switched from a NEO 550 to a Falcon 500 motor, which has been easier to code and control, but still led to the code being changed for the intake. The subteam also tuned the drivetrain constants and code logic to work better with any mechanical updates done to the robot. The new members learned about generating an auto path and the different types of ways we control the robot, as well as writing their own paths for different autos. They have yet to overcome the challenge of driving over the rendezvous bar due to prioritizing different tasks. To find more efficient paths, they have been using tests to calculate the pros and cons of a path before running it on the robot to determine if a change would speed up or slow down the robot. Some challenges they have encountered this week is losing vision on the robot, which means it loses the target every time a ball is shot and pases in front of the limelight. To overcome this challenge, they are working to program the limelight to ignore any new targets while it is shooting!

|

SOFTWARE SCOUTINg

|

Software Scouting has been getting the scouting system ready for the LA North Regional’s upcoming scout training. Front-end members are adding final touches to the match collection app, including adding a screen to edit previously mistakenly inputted match information such as team number(s) and match number. Additionally, they are preparing user documentation for match collection users at LA North. They are also making progress on pit collection by adding features to take photos of robots and mechanisms! The match strategy viewer is beginning to display data from the database, and they are beginning work on the picklist editor, which is a spreadsheet. Back-end members are communicating with MongoDB Atlas, as well as communicating with various calculations, including one to ensure that the collected data is accurate. They are also working on fixing issues with the QR scanners that are used to transfer data between the match collection app and the server.The subteam has recently had to redistribute their tasks due to recent member absences, but they continue to work together and finish important features in time for the LA North Regional!

|

BUSINESS AND MEDIAThis week, Business and Media has organized and distributed apparel to everyone on the team alongside touching up the Business Plan. The subteam has also made preparations for Sponsor Open House and inventoried the remaining apparel for the storage closet. For LA North, Business and Media is finalizing the interactive pit display and Entrepreneurship Award submission, and putting together various give-aways, including team buttons, key fobs, and stickers.

|

CHAIRMAN's

|

Chairman’s has been practicing their presentation, finishing up the documentation binder, and finishing up their prop this week. There have also been two practice presentations with parents acting as mock judges, one at the parent meeting this past Wednesday and another one for a smaller panel of parents. Thank you again to the parents that have volunteered for these practice sessions, and also to the parents that came to our parent meeting!

|

STRAtEGYThis week, the Strategy subteam has continued to finalize their e-lime-anation match strategy plans covering situations where either alliance is being overloaded. They had discussions based on the responses to our ten-ball autos and the defensive autos they predict to face. The subteam also went through corner cases, such as of having an ineffective or no-show robot on our alliance, what happens if a robot becomes incapacitated, and what happens if a single mechanism breaks on a team's robot. Finally, they thought through every scenario to determine what type of defense is best in what situations, and how incorporating the driver station visibility is a factor in how well a team can play defense. Discussing these situations can prepare our team for the worst case scenarios at competitions. The subteam also has been reading Chief Delphi posts to see what strategies other teams are thinking of. Their conversations and counter strategies help inspire the members to think of new ideas!

|

DEEP DIVE: CONTROL PANEL MECHANISM

|

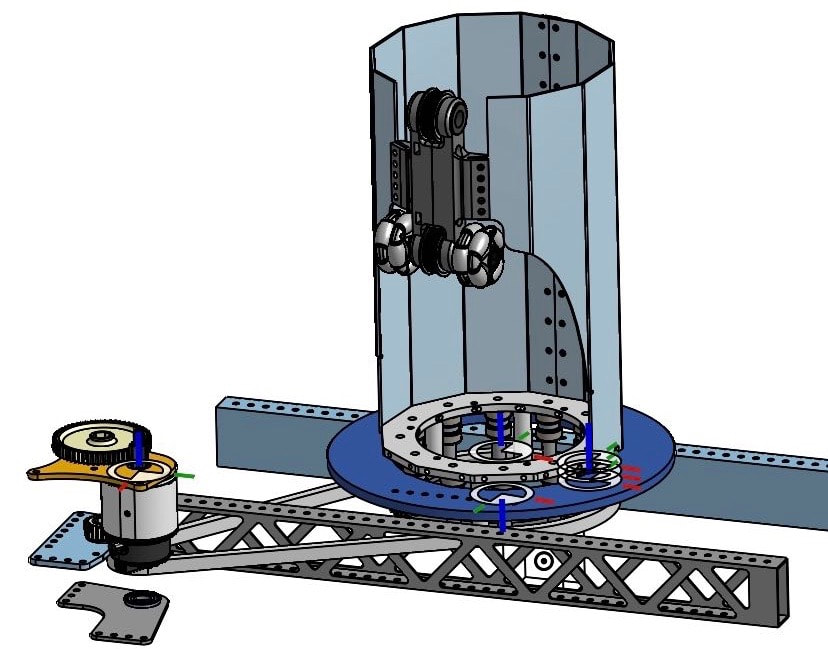

The Hardware subteams have been assembling a brand new mechanism that helps manipulate the control panel for rotation control and position control! They decided to build this mechanism to make sure our team is able to complete all tasks necessary to get a ranking point ourselves without relying on alliance partners, as we cannot control their abilities. They are working on the first iteration of the mechanism, all of the parts have been fabricated, and the members have assembled three-fourths of the mechanisms. One current issue is not having any bolts long enough on the robot to run all the way through the pivot point, which is the fixed point where everything rotates around in the mechanism. Due to this, they are waiting for a bolt they ordered to be sent here.

|

episode 6 - return of the robot

welcome!

Darth Vader once said, “I am altering the deal.” Our team has been working hard to reach our goals, and that sometimes includes returning to the robot to refine the design. Keep reading and see how each subteam jumps to lightspeed to get their work done!

Hardware fabricationHardware Fabrication has been prototyping and working on the second versions of the shooter, climber, indexer, and intake to improve performance and reliability. The telescoping elevator for lifting the robot to climb is getting fabricated for the first time, so they are waiting to see the end product before making any alterations to the robot. Getting all the work done will be challenging with one router not working, but the subteam is redistributing work and they have all hans on deck! They have also been reorganizing the shop by sorting all of the hex keys and color coordinating them.

|

hardware designThis week, Hardware Design has been working to complete a fully functional version of each mechanism and get the Competition robot fully assembled as soon as possible. Since they are currently creating two robots, the subteam has had a heavy workload. New members have been very helpful by assembling mechanisms, designing parts and small mechanisms, and helping to design the framework of the second robot! There were some mechanical issues with the accuracy of the shooter earlier this week and the Wheel of Doom hasn’t been settling balls as fast as they would like, so the subteam is designing a new shooter, indexing system, and dividing system after a thorough analysis.

|

hardware electricalThe Hardware Electrical subteam has been wiring the motors on top of the turret, checking CAN loops, making voltage dividers, and shortening wires on the CAN loop. They finished wiring most of the Beta robot and attached LEDs for signaling as well, in order to let the programmers test autos. Some challenges the subteam encountered were figuring out what was wrong with the CAN loop and figuring out how to work around mechanisms that made it difficult to wire efficiently. The members also struggled with a shortage of Anderson crimps and PWM crimps, but despite this they were able to finish wiring the robots. Hardware Electrical also received wire to build inductors for side projects.

|

software robotThis week, Software Robot has worked on programming and testing autos, and helping with bring-up on finished mechanisms. Their biggest achievement this week has been getting the ten ball auto to run within fifteen seconds. The subteam tried to cut down on time, so they made the paths as short as possible, sped up the shooting sequence, and sped up the drivetrain’s maximum velocities and acceleration, which leads to slightly faster path following. Some of the main challenges they have encountered were driving over the rendezvous bar on the floor and finding the most efficient and fastest paths for the autos.

|

|

software scoutingThis week, Software Scouting has continued to work off of their product backlog. Front-end members finished the match collection app, improved the timer feature in match collection, and added screens to the match strategy viewer that displays various information used for match strategy. Back-end members fixed bugs in the server, implemented calculations, and continued to work on connecting to the cloud database — MongoDB Atlas. Software Scouting encountered challenges while automatically generating APKs (files that contain all the code for an app that is used to install apps), but have been able to implement the automatic generation, allowing them to begin their daily end-to-end system tests. The subteam is also preparing for their next field test and upcoming scout training for the LA North Regional!

|

business and mediaThis week, Business and Media has worked on the February newsletter, a Southwest grant to lower our travel expenses this season, and is working on revising the 2019-2020 Business Plan. They have also worked on multiple smaller projects, including vinyl graphics for the Chairman's prop. Congratulations to the subteam for finishing the Entrepreneurship Award!

|

deep dive: alternative shooting mechanismHardware Mechanical and Electrical have been working on an indexer, which might replace the Wheel of Doom. Instead of spinning the power cells and putting them in slots, the new mechanism uses a funnel to get the foam balls to line up at one point. The funnel has belts on the side which leads to a tunnel that uses brushes to pull the foam balls. In addition, they added a polycord along the tunnel to lead the power cells into the shooter, which will be located at the end of the tunnel. The purpose of this prototype is to quicken the time it takes to index the power cells, since in the wheel of doom the balls take a while to settle. The prototype is basically finished, however, the subteams are still doing some more testing. One issue that the members have encountered in the past week is that the balls behave differently depending on how old they are, so they are thinking of a way to overcome the problem. Furthermore, the members of the subteams are evaluating alternatives to the brushes to move the power cells along.

|

chairman's

Chairman's has focused their force on the prop board, presentation, and documentation form after submitting the most difficult parts—the essay and executive summary--of their submission. They have a final draft of the presentation, and hope to be done memorizing by the end of the week! They are continuing to practice questions by working on how to answer different types of questions, how to incorporate stories/data that haven't been talked about yet or need to be re-emphasized, and how to fit in everything they want to tell the judges in the short five-minute questions period. For the prop, the subteam has added photos on already and started on the vinyls of our logos and programs. Parent volunteers will be acting as mock judges helping with practice presentations on Wednesdays and Saturdays.

|

strategyStrategy has reviewed Chief Delphi posts, developed our elimination match strategy, and created pickability functions used in the software scouting server. They will also begin going into corner case strategies if they have time. The new members have contributed to the discussion by asking clarifying questions and offering new ideas. The members of Strategy are rethinking autos and updating strategies since the original strategy did not pan out during robot programming tests.

|

Episode 5 - The power cells strike back

welcome!

As Han Solo once said, “Never tell me the odds!” Our team has been working very hard on our robots, and despite facing odds, everyone strikes back at challenges through the week. Have a quick luke and see where we are at!

hardware fabricationHardware Fabrication has focused on creating second quality parts, which are extra necessary parts as well as parts that need minor adjustments, and parts for the robot shooter and telescope. They have also worked on fabricating parts for Team 6814 Ellipse because their CNC Router broke. Currently, the Alpha robot is mostly assembled with a shooter, indexer, and intake, but the Beta and Competition robots are still in the process of being assembled. Once testing is finished with the Beta robot, they plan to begin fully assembling the Competition robot. The main challenge faced this week was prioritizing parts because helping Team 6814 has put some strain on the routers, however, the subteam has managed to solve this issue by distributing the parts proportionally among the four routers.

|

HARDWARE DESIGNThis week, Hardware Design worked hard to iterate and improve versions of mechanisms on to the Beta and Competition robots. Students are doing both the CAD itself as well as helping out with assembly. They have had some less than ideal performance with mechanisms such as the first version of the shooter because it is unstable and the tower it sits on has a good amount of flex that affects shot accuracy. To address this issue, they are adding upper support the second version of the shooter which they are aiming to have assembled by this weekend.

|

HARDWARE ELECTRICALHardware Electrical has completed wiring the belly pan for all three robots and has created voltage dividers necessary for the robots’ proximity sensors. They finalized how to wire the turrets, routed the pneumatic connections, and wired the mounted intake on the Alpha robot. The subteam has had to deal with shortages of materials which has made it difficult to efficiently complete their tasks, but they are luke-ing on the bright side of life and working to get more supplies!

|

SOFTWARE ROBOtSoftware Robot has been testing and working on creating autos for the intake and indexer. The challenge this week was getting the robot to make sharp turns with the presence of the steel bars within the rendezvous zone. Not having a fully assembled robot to test the autos to their full potential has also made it more difficult for the subteam to know what specific aspects need to be altered. Thank you to the new members for being so helpful and dedicating extra time to help with the current autos!

|

SOFTWARE SCOUTINgThis week, the Software Scouting subteam has conducted their first field test, in which they simulate a competition environment and scout videos of matches to find bugs in our systems. The front end continued to work on the match collection app, redesigned the user interface to include colors for the buttons and display vertically, and worked on the pit collection and match strategy view apps. The back end worked on a method to automatically download apps and files onto many devices at once. The subteam is retrieving data from The Blue Alliance and implementing calculations. They encountered many issues during the field test such as setting up the competition. Rogue-gardless, the problems have been solved and they discovered many improvements to implement for their field test next week.

|

BUSINESS AND MEDIABusiness and Media has worked on storyboarding, editing, and putting the finishing touches on a variety of videos that are being made for both our team’s and The Compass Alliance’s collection of resources. Additionally, they have continued writing the Entrepreneurship award, February newsletter, and grants.

"Do or do not, there is no try" |

CHAIRMAN's |

STRATEGY |

|

Chairman's has been working on building the prop board for presentations by painting base pieces and cutting vinyl. They have also been working on their Chairman’s video by preparing the full draft and recording the narration to be used. They have faced some issues such as not having the necessary supplies and having delays in recording the narration. Congratulations to Chairman’s for completing a few of the most difficult parts of their submission——essay and executive summary on February 3rd!

|

The Strategy subteam has determined 2020’s game to be much more strategically complex than those of previous years, due to the fact that the amount of balls available is dependent on the supply in the opponent’s alliance side and our alliance side. In response, work has been done on refining the playdesign and game flow. Because of the complexity, there’s a lot more scenarios to think through than anticipated at first. Scenarios are being run for situations where the opponents’ station is being overloaded, where there is an even flow of balls, and where our station is being overloaded.

|

episode 4 - a new design

welcome!

As Master Yoda said, “The greatest teacher, failure is.” Learned much, our team has, and we're progressing toward finishing new robot designs as we try to stay on target toward completing our robot. Follow our adventures through week four as we continue to prepare for INFINITE RECHARGE.

Hardware FabricationHardware Fabrication finished up mechanisms so our team could have the Alpha robot completed by January 26th to make changes needed to put our team in the limelight! After weeks of discussion with Hardware Design, they have settled on the first indexing system design, which is the mechanism that processes the foam balls before shooting, in order to do extensive testing. The members are also fabricating second quantities, and are working hard to make enough of every part to assemble on the Beta and Competition robot as well. The routers are running smoothly, however, they take up lots of air pressure, which makes it difficult to run other machines that also run on compressed air at the same time. To tackle this issue, they have installed a remote access application to the three small routers to make toolpaths and set up the software for the routers.

|

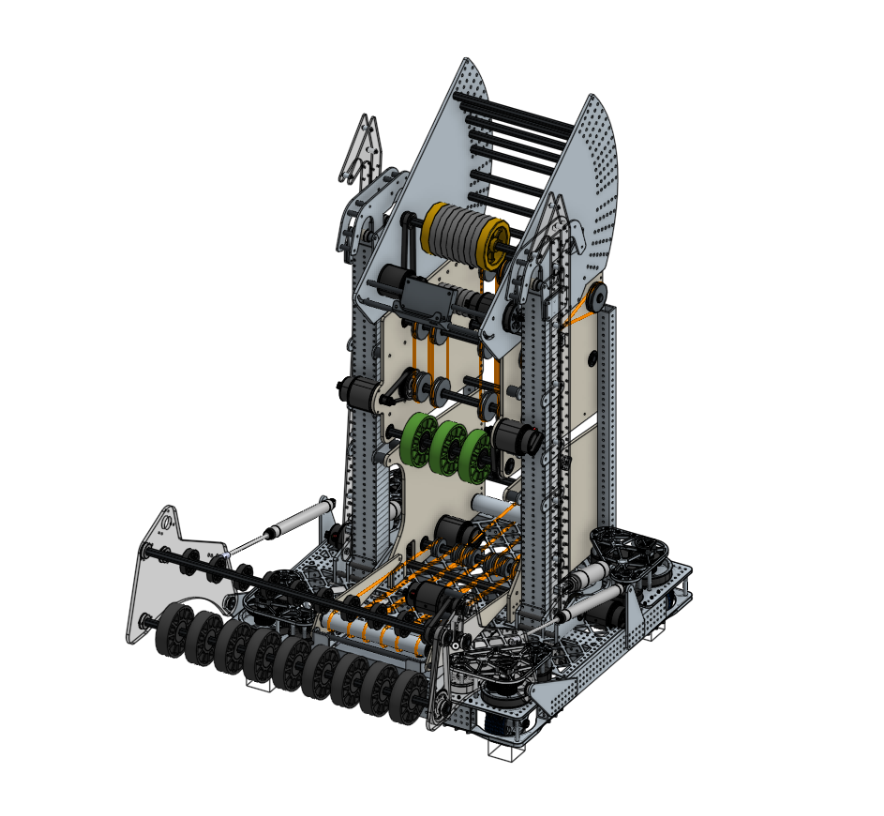

Hardware DesignIf you know a Design student, be sure to congratulate them - they’ve been putting in long hours both at the shop and at home to finish CAD designs of our robot. Their dedication has paid off, as we officially have a full first design of our 2020 robot! This year will be the first time we’ve incorporated turrets into our robot design. The hood of our shooter has been inspired by Team 254, Cheesy Poofs, and our wrangler climbing system was inspired by Team 148 Robowranglers and their 2017 buddy climb. Apart from our wrangler and turret, Design has been refining details on the indexer, telescope elevator, and intake - basically, every major mechanism. Hurray for Design!

|

Hardware ElectricalThis week, Hardware Electrical has been wiring the indexer, turret, and Falcon motors. The Falcon motors especially have made the process a lot easier, as they’re more consistent and controllable than motors from previous years. Each of the robots is about halfway done, and the team will be moving onto pneumatics of the robot soon. Most pneumatics have a chosen place already, but the specifics have yet to be determined.

|

software robotOver the past week, Software Robot has been testing individual mechanisms and finalizing the indexer, which is the mechanism that processes power cells for shooting. They’ve also been finding a way to line up the indexer with the intake so that there are no ball jams in the robot, which has been a problem with the previous designs. The shooter they’re using on this year’s robot isn’t very different from shooters in other seasons, as the only major difference is its ability to turn and shoot while moving. Once the alpha robot is finished, Software Robot will have a lot more work to do.

|

software scoutingOn the Software Scouting subteam, the front-end members are finishing up the match collection apps—apps used by scouts in the stands to collect both objective and subjective data. They’ve also worked on a pit collection app and the match strategy viewer to visualize data needed to form match strategy during qualification matches. The back-end members are continuing to program the server and work on how to log errors systematically. The subteam has experienced limitation issues on QR generation, which is used to transfer data between front-end and back-end. The QR code can only handle a certain number of character/robot actions before being unable to display, and as a result, they’ve been discussing ways to further compress info in order to continue using the QR code system.

|

deep dive: Software scouting

The Software Scouting subteam continued to work off their product backlog, which is a prioritized to-do list of features, code fixes, and other system requests. The front-end members develop and program the mobile applications used by scouts and strategists during competition, while the back-end members develop the unseen server, programming calculations, and data processing. Data is first collected by scouts in front-end applications, then it is sent to the back-end server to be processed, and finally the processed data is visualized on front-end mobile applications used by strategists. Collected and processed data is stored in MongoDB, Software Scouting’s local database, to be accessed by various parts of the scouting system (server, match collection viewer, etc.).

This year, Software Scouting switched the database it used to MongoDB, primarily because MongoDB can be hosted offline, and the competitions we attend do not have accessible WiFi to easily connect to an online database. MongoDB is also easy to set up and offers lots of documentation, which makes it is easier to implement and use than the previous database.

Recently, Software Scouting has experienced a few issues with the limitations on QR code generation. The match collection app sends collected data to the back-end server for processing via a QR code, which can only contain a certain number of characters. The front-end app generates a QR code containing compressed text of the collected data for each match (compressed so as to limit the number of characters in the QR code). However, because of the QR code character limit, the QR code would fail to generate after a certain amount of collected data, and as a result, they’ve been discussing ways to further compress the text contained in the QR code to shorten character count.

This week, front-end is finishing up the match collection apps, which are mobile apps used by scouts in the stands during competitions to collect data for match strategy and picklist formation. Front-end members integrated features into the match collection apps to collect data essential to match strategy and picklist creation of the 2020 game, including buttons to track high and low goal scoring, rotation/position control, robot incapacitation, and hang ability. They’ve also worked on a pit collection app for collecting robot data in the pits, such as drivetrain type and whether a robot can drive under the control panel. Front-end has also begun developing the match strategy viewer to visualize data needed to form match strategy during qualification matches.

Back-end is continuing to program the server by implementing basic calculations, reading and decompressing collected data, and developing the overall structure of the software. They are also working on a new method (systematic logging) to identify and fix errors, and have been developing data structures for the database (the format of collected and processed data).

This year, Software Scouting switched the database it used to MongoDB, primarily because MongoDB can be hosted offline, and the competitions we attend do not have accessible WiFi to easily connect to an online database. MongoDB is also easy to set up and offers lots of documentation, which makes it is easier to implement and use than the previous database.

Recently, Software Scouting has experienced a few issues with the limitations on QR code generation. The match collection app sends collected data to the back-end server for processing via a QR code, which can only contain a certain number of characters. The front-end app generates a QR code containing compressed text of the collected data for each match (compressed so as to limit the number of characters in the QR code). However, because of the QR code character limit, the QR code would fail to generate after a certain amount of collected data, and as a result, they’ve been discussing ways to further compress the text contained in the QR code to shorten character count.

This week, front-end is finishing up the match collection apps, which are mobile apps used by scouts in the stands during competitions to collect data for match strategy and picklist formation. Front-end members integrated features into the match collection apps to collect data essential to match strategy and picklist creation of the 2020 game, including buttons to track high and low goal scoring, rotation/position control, robot incapacitation, and hang ability. They’ve also worked on a pit collection app for collecting robot data in the pits, such as drivetrain type and whether a robot can drive under the control panel. Front-end has also begun developing the match strategy viewer to visualize data needed to form match strategy during qualification matches.

Back-end is continuing to program the server by implementing basic calculations, reading and decompressing collected data, and developing the overall structure of the software. They are also working on a new method (systematic logging) to identify and fix errors, and have been developing data structures for the database (the format of collected and processed data).

citrus serviceCitrus Service is an outreach program dedicated to helping other teams at competitions. Eight students are assigned to actively scout pits to aid other teams with any technical issues at competitions. The lead robot inspector at the 2019 Central Valley Regional, Joel Lee, stated that Citrus Service was a perfect example of FIRST’s values of teams helping other teams. In the past few years, we have worked with over 260 teams to help their robots excel in competitions. Aside from Citrus Service, we have established Service Stations, an extension of Citrus Service that is adaptable by any team at any competition. For the 2020 season, we’ve trained seven other teams to implement this program. Our team’s eventual goal is to ensure that there is at least one Service Station at every FIRST event.

|

business and media

In the past week, the Business and Media subteam has continued to document the team’s progress. Apparel designs were made to support Australian Bushfire Relief, so if you haven’t checked them out yet, here is the link: https://teespring.com/stores/frc-teams-for-bushfire-relief! The subteam sent out the team apparel order forms and has been hard at work on finalizing the offseason recap video, which will be posted this weekend. Watch our social media for the link! In addition, the members have continued to write the February newsletter, work on the Entrepreneurship award, and finish grants.

|

Thank You Parents!Thank you to all the parents who spent their time and effort to help build our field elements on Saturday, January 25, and Sunday, January 26. They look absolutely incredible, and without your help, we would never have been able to do it. We would also like to thank all of the parents for providing us meals during meetings.

|

episode 3 - revenge of the turret

Welcome !

Like BB-8, we’re rolling through week three of Build Season and almost halfway to joining an alliance to protect FIRST City. All of our team members are working together to finish the design of our robot, begin assembly of new systems, develop the programs needed to power our droid, and create a scouting system that makes sure the force is with us. Read on for more.

Hardware fabricationThe Hardware Fabrication subteam has been working on the final modifications to different prototypes, such as the shooter, turret, and indexing systems. The actual mechanisms will be based on the prototypes. The Wrangler Buddy Climb system is showing promise, and we are sticking with the original design with a few small changes. For the first time, the team will be using a turret, and they’re doing well with this new challenge at hand! They have also started to make parts for the drive train—the bottom of the robot that includes the wheels and routers--along with members of Hardware Design. Furthermore, the subteam has also finished one of the belly pans for our robot on the CNC Router. The belly pan is where the majority of electrical components and gearboxes for the wheels are located, and a CNC Router is a machine that cuts sheet metal. One challenge they encountered in the past week has been getting parts of the mechanisms done fast enough so that they can be assembled properly when needed. But other than that, Hardware Fabrication has managed to stay on track.

|

Hardware designHardware Design has been working on finishing the CAD (computer assisted design) this week for our robot, with a beta robot built on Monday. The parts to be included are the drivetrain (the wheel system of the robot), intake (where we will take Power Cells into our robot), indexer (processes the Power Cells before shooting), turret (our shooting system for the robot), and the wrangler, which will help other teams climb alongside us. New members are creating part drawings (blueprints), creating toolpaths (programs that tell our CNC router machines to cut flat plates), printing parts on our 3D printers, and putting everything together. Our turret is being revised, and the sprocket may be changed to allow better adjusting of our shooting speed. We’ve dealt with variability in our shooting accuracy and jamming in our indexer prototypes.

|

hardware electricalThis week, Hardware Electrical worked on the routing of wires on the bellypan of the robot. The bellypan includes parts such as the RoboRIO, PDP, and the PCM. The RoboRIO is the processor that holds every wiring mechanism together and keeps them running, while the PDP splits the power being spent and distributes them to all other parts, including mechanisms. The PCM, an abbreviation for pneumatics control module, will control the airflow of the robot, cooling parts down as needed. Two other key parts include the VRM (voltage regulator module), which provides power to the radio, and CANifier, which put sensors on the CAN loop, respectively. As of now, it is likely the CANifier and VRM will be placed at some part of the frame, rather than the belly pan.

|

software robotThe Software Robot subteam has been working on finalizing superstructures and subsystems from last week, and have begun to write code for the color sensor we plan on using for the Control Panel this year. For all wired mechanisms, code will be tested on them, and new vision codes will be tested to accurately measure the inner goal. Robot controls will also be written. The turret superstructure will update constantly to remember where the goal is, so that the indexer won’t be giving the shooter Power Cells too early. The drive train is also being fine tuned to follow paths properly.

|

software scoutingSoftware Scouting has been continuing to develop their scouting system, where they are currently working off of a prioritized to-do list, called a product backlog. This will be leading us to connecting the back-end servers with the front-end match strategy viewer with MongoDB, our database. As of now, Software Scouting has been split into groups of 2-4 people to complete a task, and back-end has been programming in Python, while front-end is programming the collection and visualization apps in Kotlin. The match collection app is almost finished, and in collaboration with the strategy subteam, we will be prioritizing what is most important to display on the match collection visualizer.

|

business and media |

strategy |

chairman's

|

|

For the past week, Business and Media subteam has been getting footage of build season and writing the February newsletter. In addition, the members have been working hard on the Walmart grant and Chairman’s video. The first draft of the Entrepreneurship award is almost done and we are working on the final sections! The off-season Recap video is getting finalized, and our subteam has also been designing Citrus Circuits merchandise to help Australia with disaster relief. To support Australian bushfire relief, go to: https://teespring.com/stores/frc-teams-for-bushfire-relief.

|

This week, Strategy cooperated with Software Robot to discuss the necessary actions to win a competition, and find the key(lime) to success! The members have been continuing to work on determining the data they need to create match strategy and picklists. Soon, they will think of the various scenarios they expect to encounter, and create match strategies out of those situations.

|

The Chairman’s subteam works to complete the application for the FIRST Chairman’s award, which is the most prestigious award. It represents a model for other teams, and demonstrates our goals and purposes. They have been working on various projects in the past week. They have finished writing the executive summary and essay, which will be submitted on February 3rd. The presentation team just finished their first draft, it is seven-minute presentation with a five-minute question period. The members have also been working hard on the Chairman’s video that will be released at the first competition.

|

episode 2 - attack of the droids

Welcome!

PrototypingOur hardware fabrication, design, and electrical subteams, which split into five different prototyping groups, are now working on the size and arrangement of our robot and how the mechanisms will fit into our frame. So far, we have developed a shooting method for the power cells in the game (turret), and also a “Wrangler Buddy Climb,” which uses pieces of loop tape to hook other robots into our mechanism to lift them alongside us as we climb. One concern with this system will be the amount of swing we have while climbing. We’ve decided on a 20-inch difference between the two hooks so that they’re easier to balance regardless of the portion of the Shield Generator we’ll be latched onto, like the middle, left, or right.

|

Software scouting |

Software robot |

Business and media |

|

Software Scouting has been developing a system that works on collecting data from a competition, processing and compiling the data, and visualizing the information. They have been writing the code from scratch, and will focus more on the software that is most valuable to the competition strategists. The system will be simpler, better documented, and more robust than last year. With the updates, scouts can collaborate better and the system can be more sustainable in the future. In addition, they have been figuring out what information is valuable for the picklist/match strategy this year.

|

This week the Software Robot subteam has been writing superstructures for this year’s robot, and making calculations where applicable. Superstructures are essentially a class of code that addresses a group of mechanisms, and collectively control the group to work simultaneously (for example, a finger on a gripper hand.) Calculations have also been made to test the requirements for the robot’s actions this year, and they tested the new color sensor and REV encoder.

|

This week, Business and Media has been documenting all of the students hard at work, and getting as much footage as they can! Their Offseason Recap is nearly done, so take a peep once it's up! A couple of students have been hard at work on our Entrepreneurship Award, and only the Financials and Risk Analysis sections remain. We just published our last Newsletter (take a look!) and have be working hard on next month's.

|

Deep diveThis week's deep dive focuses on Hardware Design! They've decided to put two turrets on the robot: an inner and outer turret. A turret is a rotating mechanism powered in the center by a belt or chain or around the outside with a gear profile. By adding one of the turrets onto the shooter, it will get higher resolution when aiming further away from the goal. The other turret serves as an intake, which can index the fuel cells into spinning slots so that they’re in a predictable spot when our robot shoots them to the goals.

|

episode 1 - the kickoff menace

KickoffWelcome all to Citrus Circuits Build Blog. Here, we'll describe our build season on a week by week basis, where we try to rise to the challenge of FIRST's 2020 game: INFINITE RECHARGE.

We're glad we were able to host kickoff at the Davis Senior High School for 22 teams this year! Citrus Circuits students gathered at the high school at 6:15 am to join other students in watching the reveal of the new game, which you can find here. After kickoff, students got to work discussing the new game, which you'll find out more about below! |

Infinite recharge

|

INFINITE RECHARGE is the 2020 FIRST Robotics Competition game. This year’s game is a partnership with Lucasfilm’s Star Wars: Force for Change. It involves two alliances, each with three teams. Each robot retrieves foam balls, known as power cells, from various places on the field. Then, the robots shoot them into three different goals with different values assigned to each. After scoring a certain number of balls into the goals, it can activate the control panel, a wheel with eight colored sections. By rotating or positioning the wheel to a specific color, the robot can reach the next stages in the game. At the end, the robots return to the shield generator, a rectangular structure in the center of the field, to climb and attempt to balance the switch with alliance partners.

|

|

PrototypingThis week we’ve designed parts and began putting them together. Our goals include a ten-ball auto (scoring ten power cells into the highest scoring power port.) For this game, we’ve created plans for a platform to extend out of the bottom of our robot to allow for another robot to climb up with us (called a buddy climb) and also a clamp for us to hang onto the shield generator more steadily when we climb. Some of our challenges include creating a platform that follows the rules and is also stable enough to hold another robot, and also how the platform will integrate with the rest of the mechanisms on the robot.

|

Software scouting |

software robot |

business and media |

|

Software Scouting has been developing software systems for this week, aiming for the simplest route from input to output, and to make it more simple for use on the field. They have also been determining what aspects of the game are valuable for choosing teams for our alliances and match strategy in general.

|

The Software Robot subteam has been hashing out all the logic and flow of the mechanisms on the robot. They are working towards making the shooter aim reliably throughout the match. They have also been programming a highly configurable auto. In addition, they have been working on an accurate and reliable color spinner.

|

The Business and Media team has been working on the Recap Video, entry for the Entrepreneurship award, the needed documentation for build season, securing sponsors, tracking expenditures, and a Facebook giveaway.

|

thank you parentsThank you to all of the parents: Alan Taylor, Roger Wu, Brian Hoblit, Erika Jensen, Mark Pollock, Bogart Nepomuceno, Dan Smith, Parneet Parmar, Brett Saraniti, Tom Young, James Phimmasehn, Peter Kerr, Andrew McAllister, and others, who all worked hard this weekend to build all of our major field elements and provide us with meals during meetings!

|

| whitepaper_2020.pdf | |

| File Size: | 5428 kb |

| File Type: | |