Build Blog 2016

Week 6

Salutations from our little band of merry students! We bring forth prosperous news of Adrian, our new robot that will wreak havoc among the defenses and ascend to our glorious victory in Stronghold. This is our last Build Blog as we approach the end of Build Season.

Most of the team had their hands full with preparation for Saturday, when a small group drove to the home of the Cheesy Poofs at Bellarmine College Preparatory in San Jose for a practice session on their practice field. One practice robot was brought over to the Poofs’ place to test the robot in action, as well as practice driving and timing. The team found some issues with visibility regarding the contrast between our short robot and the tall defenses, and loose wires that caused our robot to lose power. Afterwards, the group made their way to 971’s shop to speak with their mentors regarding our robot’s code.

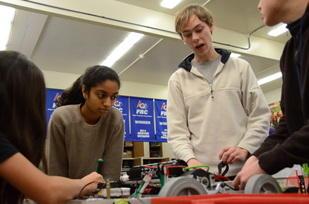

While we traversed on our perilous journey toward the Cheesy Poofs, we were paid a visit from our companions from team 5458 Digital Minds, another FRC team from Woodland that we helped start last season. They came with their robot to practice with our field elements, and received advice for their robot and its shooting mechanism.

Most of the team had their hands full with preparation for Saturday, when a small group drove to the home of the Cheesy Poofs at Bellarmine College Preparatory in San Jose for a practice session on their practice field. One practice robot was brought over to the Poofs’ place to test the robot in action, as well as practice driving and timing. The team found some issues with visibility regarding the contrast between our short robot and the tall defenses, and loose wires that caused our robot to lose power. Afterwards, the group made their way to 971’s shop to speak with their mentors regarding our robot’s code.

While we traversed on our perilous journey toward the Cheesy Poofs, we were paid a visit from our companions from team 5458 Digital Minds, another FRC team from Woodland that we helped start last season. They came with their robot to practice with our field elements, and received advice for their robot and its shooting mechanism.

|

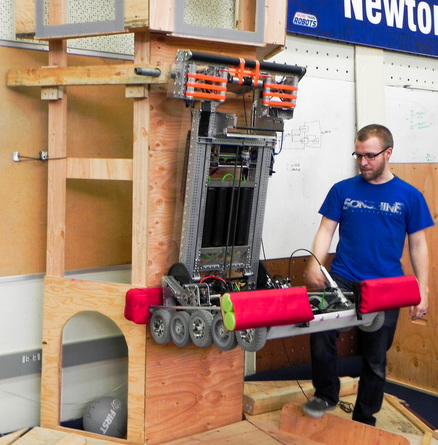

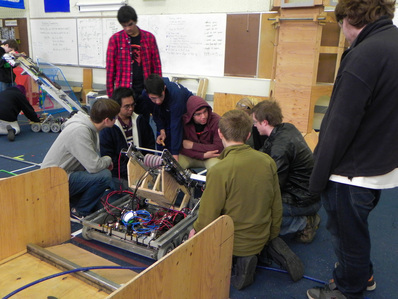

The mechanical design team is tying up all loose ends for the competition robot, which they finished Saturday for robot programming to test their code on. They are reiterating designs, continually revising and adding improvements to the competition robot in preparation for Bag Day on Tuesday.

Mechanical fabrication is taking the reiterated designs from mechanical design and incorporating them into the competition robot. One of the main parts is the defense breaker, a polycarbonate wedge used to pass the portcullis and cheval de frise defenses. This wedge is made with parts fabricated on the CNC router, the lathes, and the mills. Students are also finalizing the bumpers, intake, and other parts. |

Electrical is busy wiring all the mechanisms onto the superstructure of the competition robot. The team had some difficulties with the bridge, a wireless router that communicates between the robot and the driver. The bridge, which is a commercialized home product, is not built to endure the shock that the robot experiences when crossing the rigorous defenses. This problem was fixed, however, with the ingenious idea of bubble wrap. Currently, electrical is fixing the camera vision and adding lights onto the top of the robot as status signals.

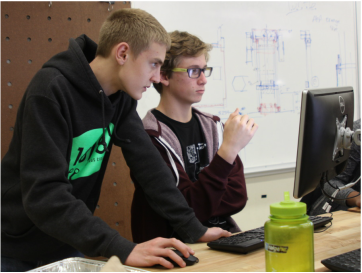

Robot programming is scrambling to finish every mechanism and program for testing this weekend. This includes the code for autonomous period, which is capable of intaking a boulder and shooting it into the high goal with no driver operating it. They have also been adjusting the camera alignment for the teleop period so that it automatically aligns to the goal, making it easier for the driver when shooting.

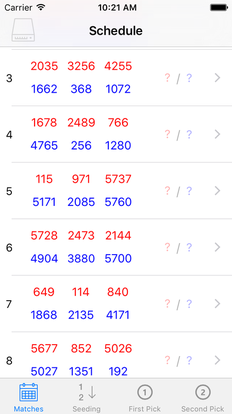

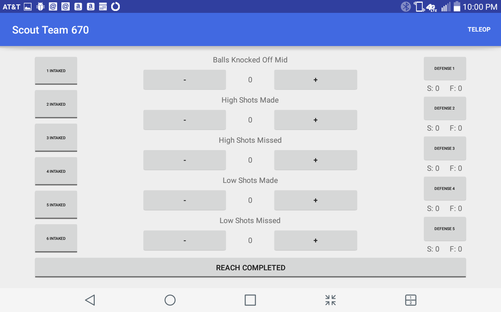

Last weekend, app programming had an enormous system test for all their scouting apps, where they found many bugs that they are currently working out. They will hold another system check this weekend, and repeat the process for every week of the season.

Robot programming is scrambling to finish every mechanism and program for testing this weekend. This includes the code for autonomous period, which is capable of intaking a boulder and shooting it into the high goal with no driver operating it. They have also been adjusting the camera alignment for the teleop period so that it automatically aligns to the goal, making it easier for the driver when shooting.

Last weekend, app programming had an enormous system test for all their scouting apps, where they found many bugs that they are currently working out. They will hold another system check this weekend, and repeat the process for every week of the season.

The students in business and media hosted a Sponsor Coffee and Doughnut Open House on Sunday, February 21, where the team provided breakfast and a tour of our new facilities to our sponsors. Additionally, we are planning for the Davis Senior High School Open House, on Thursday, February 25, from 5 to 7 PM. Invite your friends, family, and everybody you know to come into our shop and see our 2014, 2015, and new 2016 robot in action!

Thank you for reading! These final days before February 23, also known as Bag Day, will be extremely hectic as the team races to finish the robot. After bagging our competition robot, we will continue practicing and finetuning our ideas on our two other practice robots. Our first competition will be the Central Valley Regional on March 10. Be on the lookout for more news through our website, our monthly newsletters, and our upcoming reveal story.

Thank you for reading! These final days before February 23, also known as Bag Day, will be extremely hectic as the team races to finish the robot. After bagging our competition robot, we will continue practicing and finetuning our ideas on our two other practice robots. Our first competition will be the Central Valley Regional on March 10. Be on the lookout for more news through our website, our monthly newsletters, and our upcoming reveal story.

Week 5

Hail and welcome to the fifth build blog! We have had a tremendous amount of advancement this week, completing two of our practice robots and assembling the last robot, which will be our competition robot. We have only one more week of build season and everyone is working very hard to deliver the best robot possible.

The electrical team has finished wiring the second robot’s superstructure and hopes to start and finish the third robot before next weekend.

Mechanical Design has had a productive week assembling the third and final robot, which will be bagged at the end of build season on February 23. Additionally, the design team is also conducting several intake tests and putting the final touches on the two practice robots.

Mechanical Design has had a productive week assembling the third and final robot, which will be bagged at the end of build season on February 23. Additionally, the design team is also conducting several intake tests and putting the final touches on the two practice robots.

Our Business and Media Team has been working to organize the Citrus Circuits experience at Davis Senior High School’s Open House, as well as sending invitations to sponsors for our Coffee and Donut Open House. The Media team particularly has been finalizing the designs of team apparel, sponsor banner, and sponsor panel, as well as working on on several videos which highlight the team’s outreach programs and growth through the years.

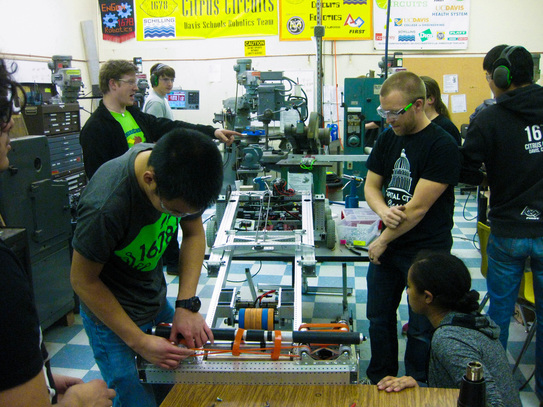

Mechanical fabrication is almost finished with the assembly of all the parts for the three robots. Most of the parts used in the three robots are identical, however the intake parts for the second and third robots have been slightly modified and improved.

This week we are beginning drive practice with one of the robots. The drive team consists of Avery Phimmasehn as the driver, Kelly Ostrom as the operator, Megan Yamoah as the human player, and Mike Corsetto as the drive coach. They’ll be testing the robot by driving through the various defenses, shooting boulders, and challenging and scaling the tower.

This week we are beginning drive practice with one of the robots. The drive team consists of Avery Phimmasehn as the driver, Kelly Ostrom as the operator, Megan Yamoah as the human player, and Mike Corsetto as the drive coach. They’ll be testing the robot by driving through the various defenses, shooting boulders, and challenging and scaling the tower.

That’s it for this week, fair thee well, and stay on the lookout for the final build blog coming soon!

Week 4

Welcome one, welcome all, to the fourth build blog! We have made a lot of progress this week on one of the practice robots and are working on completing the other two!

The electrical subteam has been busy wiring identical intake and shooter systems on all three robots. They have completed one practice robot and are finalizing the other two.

Business and media has their hands full with the Media Award and Entrepreneurship Award, both of which have upcoming deadlines. We have just submitted the essay for the Chairman's Award, the most prestigious award given by FIRST. This is the third time that we have competed for the award. The students responsible for the essay consist of Sophia Stockburger, Maya Brandy, Henry Zhang, Wesley Aptekar-Cassels, Hailey Shapiro, Javid Kasraie, and Mengxuan Zhang, led by Mme Harvey.

Business and media has their hands full with the Media Award and Entrepreneurship Award, both of which have upcoming deadlines. We have just submitted the essay for the Chairman's Award, the most prestigious award given by FIRST. This is the third time that we have competed for the award. The students responsible for the essay consist of Sophia Stockburger, Maya Brandy, Henry Zhang, Wesley Aptekar-Cassels, Hailey Shapiro, Javid Kasraie, and Mengxuan Zhang, led by Mme Harvey.

|

Mechanical design is gradually assimilating into fabrication, with only a few details to work out on CAD. Overall, however, they are virtually finished, and have started making parts alongside the mechanical fabrication subteam in the shop.

This has been a very productive week for mechanical fabrication, as they have finished producing all current designs for one of the robots. After making a few modifications, students have assembled 85% of this robot and anticipate practicing with it next week. That’s about it for this week, but be sure to check back next week for another build blog, and remember to have a phenomenal week! |

Week 3

Hear ye, hear ye, for the weekly build blog! Gather ‘round the bonfire for a glorious tale of the third week of Citrus Circuits as we prepare to breach the defenses and capture the tower.

This is the closing week for mechanical design, in which they are finalizing all of the mechanism sketches on the CAD program. Each member is working on a different part, from the elevator to the intake, and converting the part drawings into dxf files. Dxf files are used on the CNC router, which is a machine in the shop that allows us to make parts efficiently by directly translating the computer design onto metal, which we then incorporate into our robot. Once all the files are finished, the mechanical design team will slowly transition and merge with the mechanical fabrication team.

Mechanical fabrication is busy using the various mills, lathes, and the CNC router to make all in-house robot parts.The term “in-house” is used for parts which are created in our own mechanical shop. Parts that may be too complicated or time-consuming are ordered from outside fabricators, including Aerometals and Martin’s Metals, but the majority of our robot is built in the shop. This week, the group is taking the drawings made by the design team and producing components for the intake and the shooter.

This is the closing week for mechanical design, in which they are finalizing all of the mechanism sketches on the CAD program. Each member is working on a different part, from the elevator to the intake, and converting the part drawings into dxf files. Dxf files are used on the CNC router, which is a machine in the shop that allows us to make parts efficiently by directly translating the computer design onto metal, which we then incorporate into our robot. Once all the files are finished, the mechanical design team will slowly transition and merge with the mechanical fabrication team.

Mechanical fabrication is busy using the various mills, lathes, and the CNC router to make all in-house robot parts.The term “in-house” is used for parts which are created in our own mechanical shop. Parts that may be too complicated or time-consuming are ordered from outside fabricators, including Aerometals and Martin’s Metals, but the majority of our robot is built in the shop. This week, the group is taking the drawings made by the design team and producing components for the intake and the shooter.

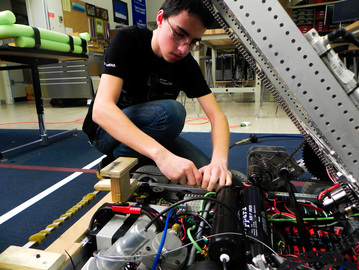

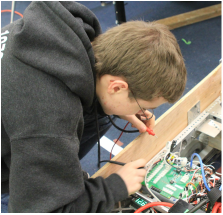

After completing the wiring on both practice robots, the electrical team has circled around the competition drivetrain, and are all working in a frenzy to finish it. This includes wiring the battery into the power distribution panel and applying the pneumatics for shifting gears. The completed practice robots are being loaded with the drive code that the programmers wrote. There were a few problems regarding the calibration of the tuning constants, but that is currently being rewritten.

Besides the drive code, the robot programmers are further developing the vision program, adding in code that allows the robot to target and turn toward goals for shooting, and inputting logging, which records errors and values for future outcomes. Other members have started on the elevator mechanism code, where they are modeling the system to prepare for control programming.

App programming is preparing the scouting server for weekend practice, in which they will test their current draft and take notes on what to improve on. From now on, the scouting system will be put through an endless cycle of testing and revising.

This has been quite a week for business and media. After refurbishing our room with new carpet, the group has finalized the t-shirt and sweater designs, with orders due on February 5th. Aside from that, we are also writing the February newsletter, preparing for an upcoming presentation with the Blue and White Foundation, and documenting build season progress through photos, videos, and the build blog.

This has been quite a week for business and media. After refurbishing our room with new carpet, the group has finalized the t-shirt and sweater designs, with orders due on February 5th. Aside from that, we are also writing the February newsletter, preparing for an upcoming presentation with the Blue and White Foundation, and documenting build season progress through photos, videos, and the build blog.

Thank You To Our Parent Lunch Team

Thank you to all the parents who have and will bring lunches for us every weekend! The entire team is very grateful for the daily nourishment that you provide us, which replenishes our energy and motivates us to keep on working. We appreciate the diversity of foods and treats the parents bring, and are eager to get seconds and maybe even thirds! Again, thanks so much for the continued support, and we look forward to more delectable meals!

Week 2

Welcome back, everyone, to the build blog! The second week of build season is completed, and we’ve made tremendous progress on all aspects of the robot.

This time, we’ll switch it up a bit and start with the programmers! Currently, the robot programmers are improving their vision program by updating the algorithm to determine distance and angles, and calibrating it to calculate tuning values faster. This will all be applied to 20 different routines, which will be used during the autonomous period of a match. Once they have finalized the vision program, they will begin programming the intake and shooter mechanisms.

This time, we’ll switch it up a bit and start with the programmers! Currently, the robot programmers are improving their vision program by updating the algorithm to determine distance and angles, and calibrating it to calculate tuning values faster. This will all be applied to 20 different routines, which will be used during the autonomous period of a match. Once they have finalized the vision program, they will begin programming the intake and shooter mechanisms.

Meanwhile, the app programmers are further developing their scouting system by integrating prediction algorithms into their server. Each new update is being repeatedly tested on a synthesized model database, and revisions are constantly being written back into the code.

The prototyping groups have dispersed and gone back into their initial sub-teams: electrical, mechanical design, and mechanical fabrication. Everyone there is hard at work enhancing the prototypes made by the various prototyping groups.

The prototyping groups have dispersed and gone back into their initial sub-teams: electrical, mechanical design, and mechanical fabrication. Everyone there is hard at work enhancing the prototypes made by the various prototyping groups.

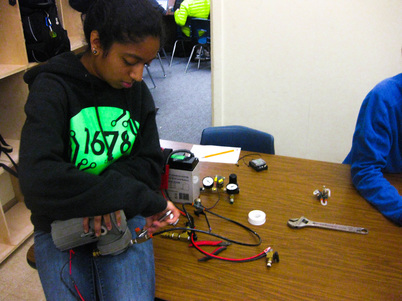

This week is one of the most important times of year for the electrical team. They have spent the entire week testing and organizing wires and parts for this upcoming weekend. This includes the pneumatic parts, which use pressurized air in tubing and valves to move cylinders, and electrical parts, such as batteries and multicolored wires. All of this will be assembled onto the drivetrain, where they are wiring the belly pan - a laser cut piece of aluminum to which all the electronic parts are mounted.

Mechanical Design has been bent over their computers for the majority of the week, working with the CAD program. Each member is responsible for a different part of the robot, from the shooting and intake system to the pivoting elevator used to scale the tower. Essentially, the entire superstructure (everything except the drivetrain) is being drafted. This will be completed by Sunday and shipped off to fabrication to be built.

Mechanical Design has been bent over their computers for the majority of the week, working with the CAD program. Each member is responsible for a different part of the robot, from the shooting and intake system to the pivoting elevator used to scale the tower. Essentially, the entire superstructure (everything except the drivetrain) is being drafted. This will be completed by Sunday and shipped off to fabrication to be built.

The mechanical fabrication team is taking the drafts produced by their design counterparts and creating parts to be assembled onto the robot. Right now, they are cranking out parts for the drivetrain, which they sent to electrical on Friday.

And lastly is the business and media team. This group handles all of the sponsors, writing, and media relevant to the team. Currently, they have been updating the website, compiling the video for the Chairman’s Award, finalizing the sponsors for the t-shirt and banner, and writing the build blog that you are reading right now.

And lastly is the business and media team. This group handles all of the sponsors, writing, and media relevant to the team. Currently, they have been updating the website, compiling the video for the Chairman’s Award, finalizing the sponsors for the t-shirt and banner, and writing the build blog that you are reading right now.

Thank You To Our Parent Build Team!Everyone on the team would like to give a shout-out to all the parents who helped work on the various field elements for this year’s game! A big thank you to Paul Brandy, Buck Cutting, Steve Furman, Dan Hahn, Mark Moeller, and Steve Strickland for taking time out of their schedules to build everything we needed. Stronghold has the most complicated field that we’ve seen so far, and we greatly appreciate all the support and effort that went into making this happen. It is a huge advantage for the team to practice on the newly constructed field, especially during prototyping, as we can test our ideas without having to finalize them first. Again, thank you so much!

|

Week 1

Hello everybody! Welcome to the first week of build season, which, as many of you know, is a very hectic yet fun time of the year.

We started off with kickoff last Saturday, January 9, where around 60 students drove to Kennedy High School to watch the unveiling video with teams throughout the region. This year’s game is Stronghold, where teams must break through obstacles and capture the opponent’s tower. Click here for the reveal video or here for the official game manual |

Right after kickoff, the team hurried back to headquarters to begin our three stage approach to build season. The first stage is the rules test, where the team memorizes the manual and takes our 32 question test. The rules test, which is written by students immediately after kickoff, is a ruthless interrogation of the most important components in the game manual. Once everyone passes the rules test, the second stage is a thought-provoking discussion of our upcoming strategy, which is initiated by student presentations. After the confirmation of our strategy, we began the third stage of designing our robot, which is again led by student presentations. The team then finalizes the basic details of how our robot should operate, and we move on to prototyping.

The mechanical and electrical teams combine to make multiple prototyping groups, where they work to develop a certain aspect of the upcoming robot! Right now, we have a scaling, intake, shooting, field elements, and drive team and defense group.

The scaling team is in charge of figuring out how the robot will attach onto the rung on the tower at the end of the match. For those of you unfamiliar with the rules, if a robot manages to grapple onto the rung on the tower within the last twenty seconds of the match, a total of fifteen points will be added to the score of that robot’s alliance. So far, the group has been reviewing their proof of concepts, where they analyze off-season robots in order to determine the amount of power needed to lift a robot’s weight linearly and rotating. They’ve also changed the gearboxes, which are used to change the speed of a motor, and examine multiple different hook designs, to be used on the robot.

The scaling team is in charge of figuring out how the robot will attach onto the rung on the tower at the end of the match. For those of you unfamiliar with the rules, if a robot manages to grapple onto the rung on the tower within the last twenty seconds of the match, a total of fifteen points will be added to the score of that robot’s alliance. So far, the group has been reviewing their proof of concepts, where they analyze off-season robots in order to determine the amount of power needed to lift a robot’s weight linearly and rotating. They’ve also changed the gearboxes, which are used to change the speed of a motor, and examine multiple different hook designs, to be used on the robot.

The intake team’s job is to create an intake system for collecting “boulders” (the balls being used for the match). Currently, they are assembling the prototype, which will gather boulders directly from the field.

The shooting team is responsible for the shooter and its capability to launch boulders into the openings at the top of the tower. The plan for the shooter is to have a shaft - a structural element used to transfer power - with wheels on the bottom and a hood on the top to guide the ball in the shooting direction. This week, the group experimented with shaft heights and hood dimensions.

The field elements group builds the field components, including the defenses and tower. Thus far, the group is constructing the drawbridge and sally port (two kinds of defenses) and hope to finish all elements that do not involve steel by the end of the week.

The drivetrain and defense team is accountable for the base of the robot and the how it will traverse the field defenses. The group sketched out their prototype of a ten wheel base, which is scheduled to be finalized by Saturday.

The shooting team is responsible for the shooter and its capability to launch boulders into the openings at the top of the tower. The plan for the shooter is to have a shaft - a structural element used to transfer power - with wheels on the bottom and a hood on the top to guide the ball in the shooting direction. This week, the group experimented with shaft heights and hood dimensions.

The field elements group builds the field components, including the defenses and tower. Thus far, the group is constructing the drawbridge and sally port (two kinds of defenses) and hope to finish all elements that do not involve steel by the end of the week.

The drivetrain and defense team is accountable for the base of the robot and the how it will traverse the field defenses. The group sketched out their prototype of a ten wheel base, which is scheduled to be finalized by Saturday.

And last, but not least, are the programmers. Separated into robot programming and app programming, in which they design the scouting system used at competitions, the programmers are working hard in preparing for the upcoming season.

This week, the robot programmers are setting-up the computers and the Roborio - the main computing unit for the robot. One crucial feature added to the Roborio is vision, a program that utilizes cameras to identify objects. This will be used for the autonomous period in a match, when the robots operate independently of human control.

On the other hand, the app programmers are discussing the upcoming scouting system and how to apply it to the new game. This includes elements that should be scouted for and how the scouting system should operate.

That’s it for this week, but be on the lookout for more build blogs, released weekly, and have a magnificent week!

This week, the robot programmers are setting-up the computers and the Roborio - the main computing unit for the robot. One crucial feature added to the Roborio is vision, a program that utilizes cameras to identify objects. This will be used for the autonomous period in a match, when the robots operate independently of human control.

On the other hand, the app programmers are discussing the upcoming scouting system and how to apply it to the new game. This includes elements that should be scouted for and how the scouting system should operate.

That’s it for this week, but be on the lookout for more build blogs, released weekly, and have a magnificent week!