Drivetrain |

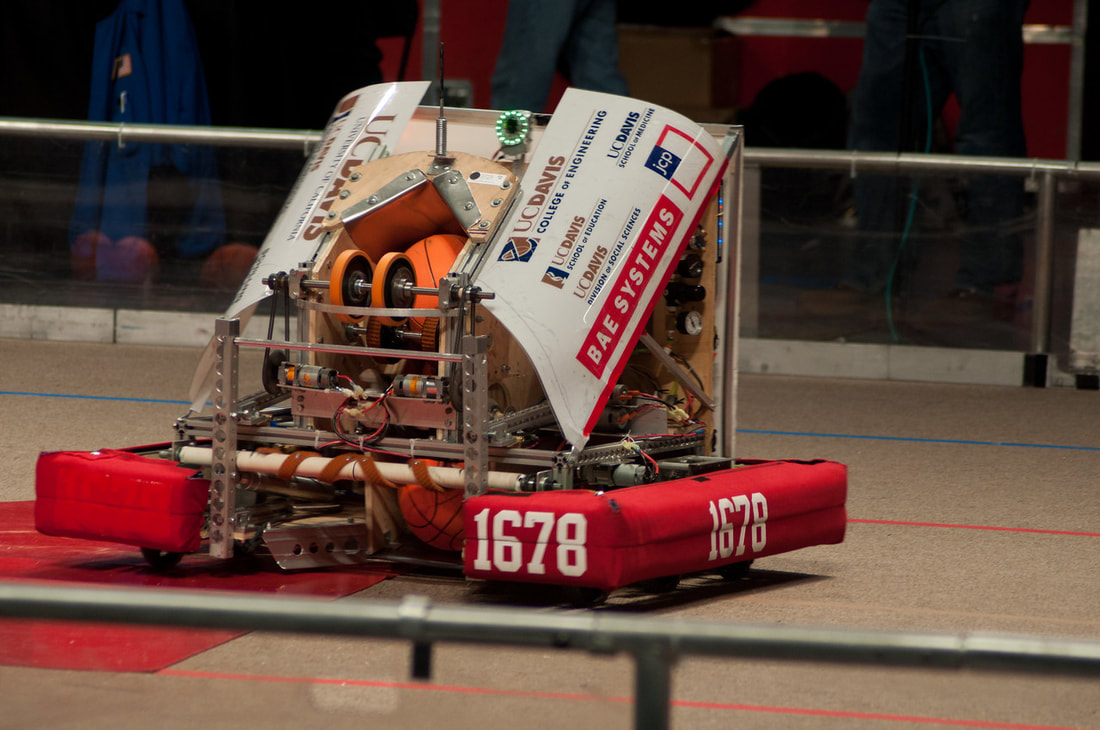

The Juicer has a six-wheel drop center tank drive (for ease while turning) powered by four CIM motors and two gearboxes.

|

Scoring |

The Juicer’s scoring mechanism involved a track that led up to two shooter wheels. The shooter wheels were covered in a high-traction rubber and were spinning at 12,000 RPM. Due to our fast-spinning wheels, our high compression upon the ball’s exit, and the large amount of backspin applied to the basketballs, our shooting mechanism was very accurate.

|

Bridge manipulators |

To force the bridge down in order to drive up on to it, the Juicer had two metal arms lined with a low-friction plastic. The arms deployed in front of the robot and used a pneumatic locking system for stability. After deploying the bridge mechanisms, the Juicer was then able to basically ram the bridge, and the arms acted as rails upon which the Juicer would slide. The weight of the robot then pushed the bridge down.

|

Control/ electrical system |

The Juicer’s control system used wi-fi communications and a National Instruments cRIO, implemented by FIRST in 2009. Motors are controlled by Victor speed controllers, pneumatics are controlled by Vex Pro Spike relays and solenoids. Sensors included a limit switch for detecting the location of balls within the shooting mechanism and encoders for the drive train.

|

Operator interface |

The Juicer was controlled by three joystick controllers: two for the driver and one for the manipulator, who controlled the shooting mechanism. The driver used tank drive, meaning that one joystick controls one side of the drive train. The manipulator pushed a button to set up the system for shooting, another button to start the high speed shooter wheels, and then finally a trigger to shoot, with very little effort required on the part of the manipulator as the robot monitored the shooter speed and the location of the balls within the robot.

|

Achievements |