Lemon Squeeze2009

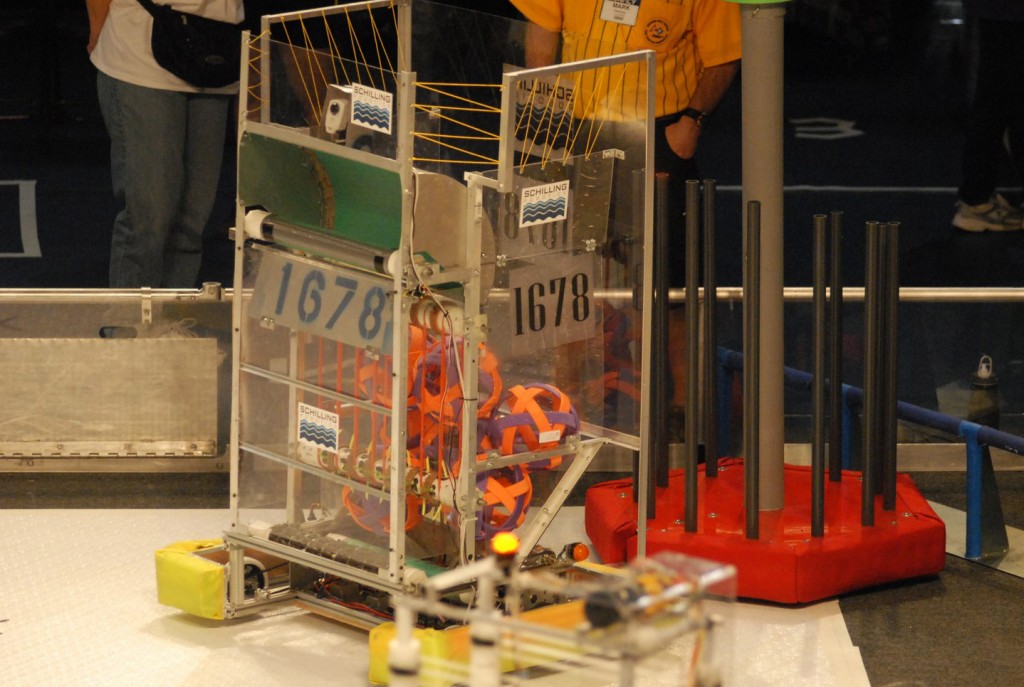

Our 2009 competition robot was named “Lemon Squeeze: Juice Master 1678.″ It was capable of both picking up stray “moon rocks” from the ground and receiving moon rocks thrown by the payload specialist. The moon rocks were stored in the hopper, with a maximum capacity of 30 balls. When ready to score, a conveyor belt system carried the balls up and out of the robot, shooting them at point-blank range into our opponent's trailer. It took less than 10 seconds for Lemon Squeeze to unload a full hopper.

|

drivetrain |

Lemon Squeeze used a four-wheel drivetrain powered by two CIM robot motors and two gearboxes. The wheels were the low-friction “rover wheels” required for 2009’s game.

|

ball-handling systemcontrol/ electrical systemoperator interface |

Most of the robot’s bulk consisted of a hopper, built out of Plexiglas, which was capable of storing more than 20 balls. A conveyor system in the front moved balls into the shooter or hopper, and a “pickup roller” in the front sucked them from the floor or spit them into a player station. The ball-handling system was designed to be easily reconfigured while in play–for example, to segregate an empty cell from the rest of the balls, the robot could reconfigure its conveyor and pickup system as a secondary hopper.

Lemon Squeeze’s control system was built on an entirely new platform utilizing wi-fi communications and a National Instruments Compact Rio system. In total, the robot has eight on-board processors, which are controlled by the CPU in the Compact Rio. Lemon Squeeze’s software could automatically monitor the robot’s acceleration and prevent the wheels from slipping using an accelerometer. The software could also perform other tasks to make driving the robot easier, such as automatically compensating for changes in heading caused by drag from the trailer. When preparing to dump balls into an opponent’s trailer, Lemon Squeeze used a camera to “lock on,” allowing for very high precision in lining up for an attack. Lemon Squeeze could even track a target if it went out of its field of vision–a technology called “predictive tracking” that allowed the robot to guess where it should look.

Lemon Squeeze was driven with two joysticks using a tank drive system. A second driver operated a third joystick that controlled the robot’s ball handling system.

|